10 Real Estate Software Development Companies in 2025

- February 03

- 9 min

Integrating facility maintenance into property management software means creating a single, centralized system to manage all upkeep tasks for assets like HVAC units and elevators. This approach moves property managers away from manual tracking toward an automated, efficient process. It improves oversight, reduces costs, and helps maintain high tenant satisfaction.

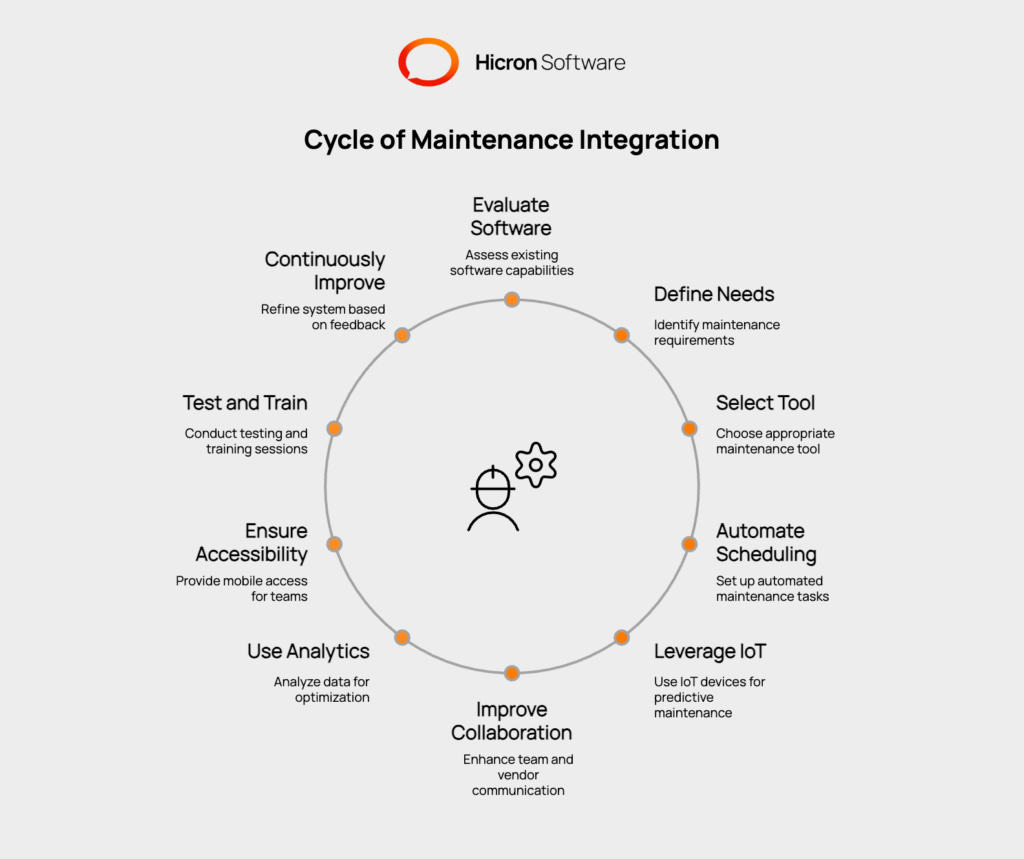

This article explains how to connect maintenance scheduling with your property management software. It provides a step by step guide to help you build a more effective system for tracking and managing your property’s assets. You will learn how to assess your current tools, define your needs, and use technology to automate upkeep.

Key Takeaways:

The first step is to understand what your existing property management software can do. Look for a built in maintenance module. Many modern platforms offer features for creating work orders, scheduling jobs, and managing vendors. If your software has these functions, your main task will be to configure them for your properties.

If a native module is not available, check if the software offers an Application Programming Interface (API). An API allows different software programs to connect and share information. This is necessary if you plan to use a separate maintenance management tool. You can find this information in your software’s documentation or by contacting its support team.

Next, create a detailed plan of your maintenance needs. This plan will guide your integration process and ensure the final system meets all your operational goals.

Start by making an inventory of all equipment requiring regular service. This includes HVAC systems, elevators, fire alarms, and plumbing fixtures. For each asset, note its location, manufacturer, and age. Then, establish the maintenance schedule for each piece of equipment based on manufacturer advice or legal requirements. Finally, list your service providers and their contact details.

With a clear plan, you can select the right solution. You have three main options. If your property software has a built in module, this is the most direct path. You can start by adding your asset list and setting up recurring schedules.

If your software lacks the right features but has an API, you can connect it to a specialized maintenance tool like UpKeep or Fiix. These platforms offer advanced features for asset management and can sync data with your main property system. For unique or large-scale operations, developing a custom solution may be the best choice for maximum control.

Automation is a primary benefit of an integrated system. It eliminates the need for manual tracking and frees up your team for other duties. You can set up recurring work orders for all preventive maintenance tasks. For example, schedule an automatic work order for an HVAC filter change every three months.

You can also create trigger-based alerts. By connecting smart sensors, the system can automatically generate a work order when a problem is detected. An alert could be triggered if an HVAC unit’s performance declines or a pump shows irregular pressure. This allows you to address issues before they become major problems.

You can improve your maintenance process further with Internet of Things (IoT) devices. Smart sensors installed on equipment provide real time data on performance and condition. For example, vibration sensors on an elevator motor can detect small changes that point to a future failure.

This data streams directly into your property management software, triggering alerts for predictive maintenance. Instead of reacting to equipment failures, you can schedule repairs proactively. This approach reduces downtime, cuts emergency repair costs, and helps your assets last longer.

A good integrated system acts as a central hub for all communication. This removes the need for constant phone calls and emails. You can give your external service providers access to a vendor portal where they can see work orders, post updates, and submit invoices.

Inside the platform, you can assign jobs to your internal staff or external vendors. Technicians can view their assignments and deadlines directly in the system. This makes sure everyone has the correct information and knows their responsibilities.

An integrated system gathers useful data for optimizing your operations. Use your software’s reporting features to track maintenance history, costs per asset, and equipment downtime. Analyzing this information helps you spot trends and make better decisions.

For example, you might find that one brand of air conditioner needs more repairs than another, which can inform your future purchases. You could also see how preventive maintenance has lowered the number of emergency calls, demonstrating the value of your program.

Maintenance work happens on site, not at a desk. Your system must be accessible from anywhere through a mobile application. A mobile friendly platform lets your team receive work orders, update job statuses, and add notes from their phones.

Push notifications can instantly alert a technician about a new high priority task. This real time access improves response times and team efficiency. It empowers your staff to manage their work effectively while in the field.

After setting up your system, test it thoroughly. Start a pilot program at one or two properties to find and fix any issues. Check every function, from creating a work order to processing an invoice, to make sure the process is smooth.

Once testing is complete, provide training for everyone who will use the system. This includes property managers, maintenance staff, and vendors. Clear instructions and hands on practice will help ensure everyone uses the new tool correctly.

An integrated maintenance system should evolve with your business. Watch its performance and ask users for their feedback. Look for any recurring problems or ways to improve the workflow.

Use this feedback to make regular adjustments. Review your analytics reports to find new opportunities for improvement. A process of continuous refinement will ensure your system provides lasting value.

The main benefit is centralization. It brings all maintenance tasks, schedules, and communications into one place, which improves efficiency and reduces manual errors.

Yes, if your software has an open API, you can connect it to third party maintenance management tools that offer the features you need.

Predictive maintenance uses data from IoT sensors to detect potential equipment failures before they happen, allowing you to schedule repairs proactively.

A vendor portal gives your service providers direct access to view assigned work orders, update their status, and communicate with your team, which simplifies coordination.

Mobile access is critical because maintenance staff work in the field. It allows them to receive and update tasks in real time from their smartphones, improving response times and efficiency.