Definition: Automating preventive maintenance is the use of technology, such as IoT and AI, to proactively monitor, predict, and address maintenance needs in building systems, ensuring efficiency, reducing costs, and preventing unexpected failures.

Automating preventive maintenance in work order management is transforming the way property managers handle building operations. By integrating IoT and AI technologies, this approach enables real-time monitoring of critical systems, such as HVAC units and plumbing.

Predictive maintenance ensures potential issues are identified early, reducing costly repairs and improving operational efficiency. IoT integration for property management, combined with AI-driven property insights, plays a pivotal role in streamlining workflows and enhancing energy efficiency. This article explores the benefits of automation, from reducing manual errors to enhancing tenant satisfaction, highlighting how these technologies drive long-term value and sustainability in property management.

Key takeaways

- IoT integration for property management enables real-time monitoring of HVAC systems, plumbing, and other critical equipment, allowing for proactive maintenance and improved operational efficiency. This proactive approach prevents costly repairs and ensures operational efficiency.

- AI-driven property insights analyze sensor data to predict maintenance needs. This reduces manual errors, improves decision-making, and enhances workflow automation.

- Automate preventive maintenance in work order management to monitor energy usage. IoT sensors and AI analytics detect inefficiencies, ensuring sustainable and cost-effective operations.

- Centralized property management systems powered by IoT and AI automate work order generation, task assignments, and vendor coordination, saving time and reducing delays.

How IoT sensors enable predictive maintenance in property management?

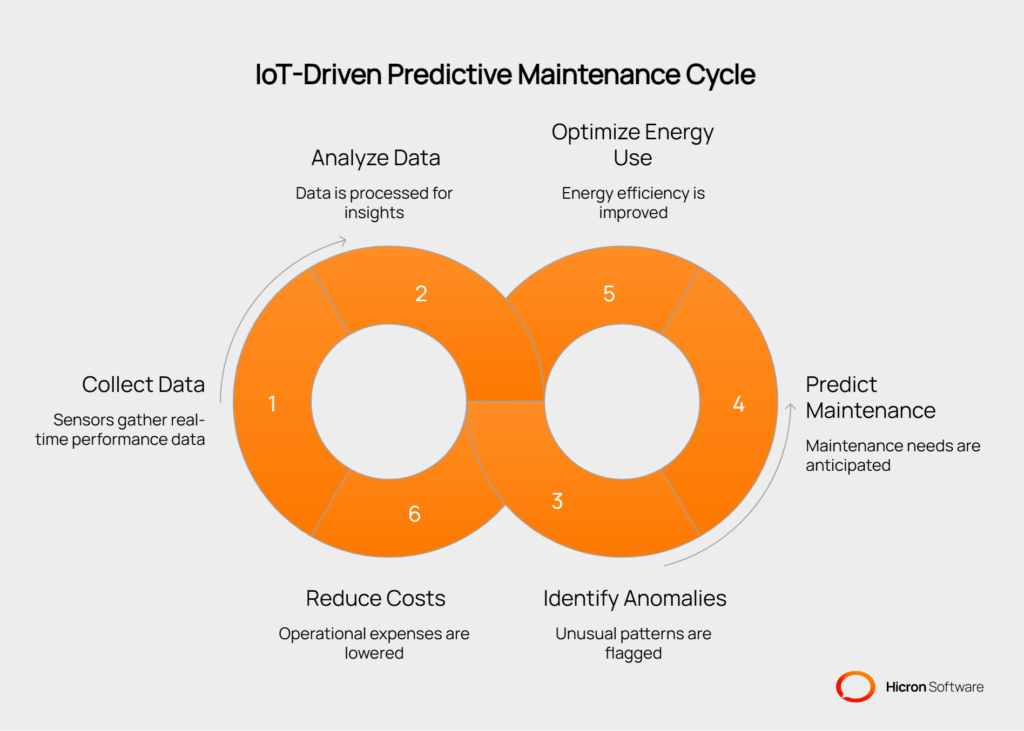

IoT Integration for property management utilizes a network of interconnected sensors to continuously monitor HVAC systems, pumps, elevators, lighting, and other essential building equipment. IoT sensors collect and transmit performance data, such as temperature, humidity, vibration, and energy consumption, in real-time, providing property managers with immediate insights into equipment health.

Once gathered, this granular data is instantly processed using real-time data analytics platforms that benchmark readings against optimal baselines.

For example, these systems can flag anomalies such as excessive vibration in HVAC motors (signaling potential bearing failure), sudden temperature spikes (pointing to refrigerant leaks), pressure drops in pumps, or irregular run-time patterns suggesting unnecessary energy consumption.

With real-time data analytics, IoT integration for property management transforms raw data into actionable insights, allowing managers to predict maintenance needs and prevent costly equipment failures. Additionally, IoT sensors enhance energy efficiency monitoring by identifying excessive energy usage or system imbalances. This enables timely corrections that reduce operational costs and environmental impact.

By adopting IoT-driven predictive maintenance, property managers can ensure smoother operations, extend the lifespan of equipment, and optimize energy use. This proactive approach is essential for modern, scalable property management.

AI-driven insights to automate preventive maintenance needs

AI-Driven property insights leverage advanced algorithms to analyze vast amounts of sensor data in real time, including readings from

- temperature monitors,

- vibration sensors,

- run-time logs,

- automated fault detection codes.

Through continuous monitoring and machine learning, AI can establish a baseline for equipment performance and quickly detect subtle deviations that may signal early signs of wear or impending failure.

By applying predictive analytics for market trends to property management, these platforms can forecast when components like

- HVAC systems,

- elevators, or

- pumps

need preventive maintenance, allowing property managers to plan ahead and avoid disruptive breakdowns. This proactive maintenance strategy extends asset lifespan and reduces unforeseen repair costs, contributing to long-term operational efficiency.

AI-driven predictive analytics streamline workflow and decision-making by automating diagnostics and providing prioritized, actionable recommendations based on risk assessments.

Automated alerts and intelligent ticketing ensure critical issues are addressed, while less urgent tasks are scheduled. This minimizes downtime and tenant inconvenience. Importantly, AI-backed systems are designed to eliminate human guesswork, reducing manual errors that can result from subjective judgment or overlooked maintenance schedules.

AI-driven insights empower decision-makers to transition from reactive to proactive maintenance, extending equipment lifespan, preventing downtime, and optimizing operational efficiency. The adoption of predictive analytics ensures a smarter, data-driven workflow that supports long-term value in property management.

Streamlining work order management with IoT and AI integration

Effective work order management is crucial for efficient property operations. By integrating IoT and AI with centralized property management systems, property managers can automate the process of generating, assigning, and tracking work orders. This advanced integration streamlines workflows, reduces manual errors, and improves overall operational efficiency.

Automated work order generation and assignment

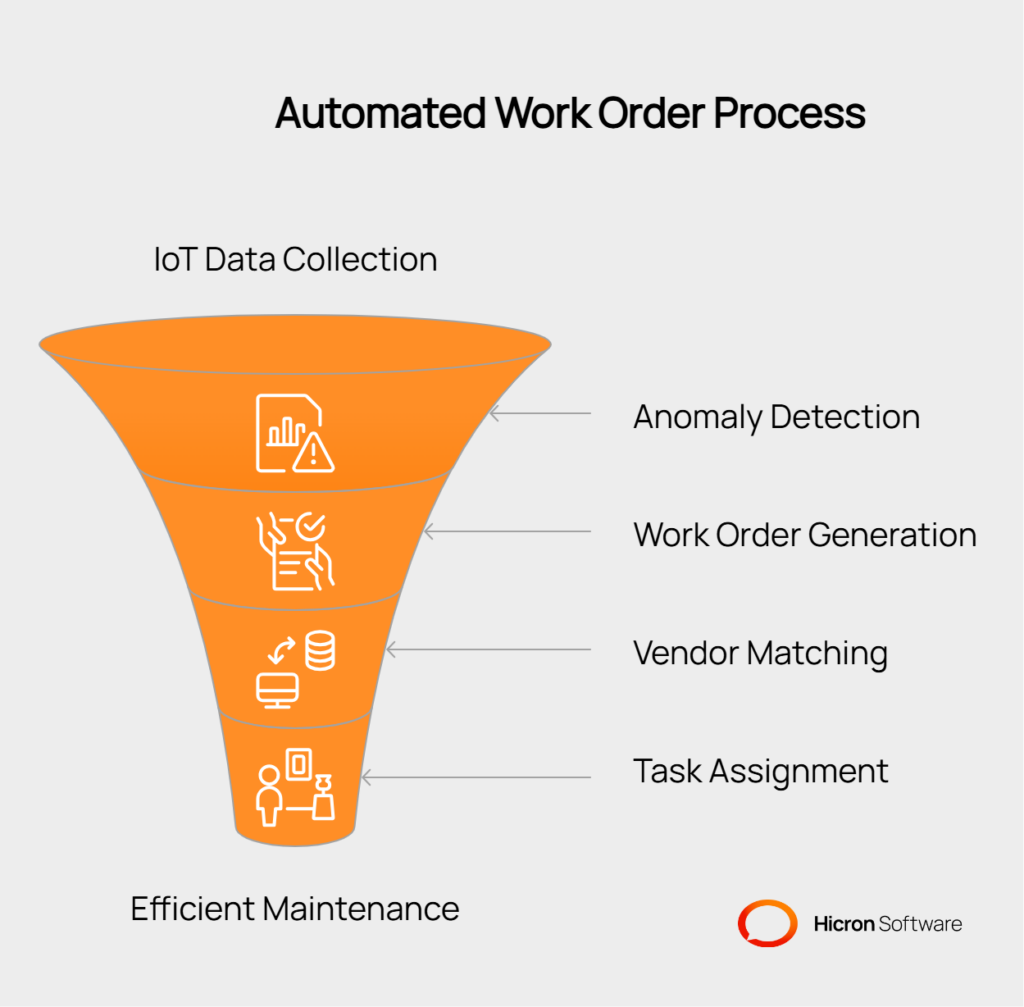

IoT devices, such as sensors and smart meters, continuously monitor building systems like HVAC units, lighting, and plumbing. These devices collect real-time data on system performance and transmit it to a centralized platform.

When anomalies or maintenance needs are detected, the centralized property management system automatically creates a work order.

For example, if a sensor identifies a temperature drop in an HVAC system, the automated work order generates a repair request instantly, eliminating delays caused by manual reporting.

With intelligent automation, maintenance issues are never missed, and response times improve. Once a work order is created, the system uses specific criteria, including

- vendor location,

- certifications,

- response history,

- workload, and

- availability.

This matching process assigns each task to the service provider best positioned to resolve the problem. Vendors receive all needed diagnostics and real-time context before arriving, enabling quicker and more precise repairs.

This workflow automation ensures issues are addressed promptly, reducing equipment downtime and enhancing tenant satisfaction.

By adopting this state-of-the-art technology, property managers gain a solution that supports them in managing day-to-day operations.

Also check service for common real estate software development.

Integration with property management tools

Integration with accounting, inventory, procurement, and compliance platforms ensures data flows between departments, eliminating duplicate entries and streamlining administrative tasks.

By integrating IoT and AI, property managers can resolve issues more efficiently, reduce operational costs, minimize downtime, and make data-driven decisions to enhance building performance and tenant satisfaction over time.

Using AI to differentiate emergency and non-emergency maintenance

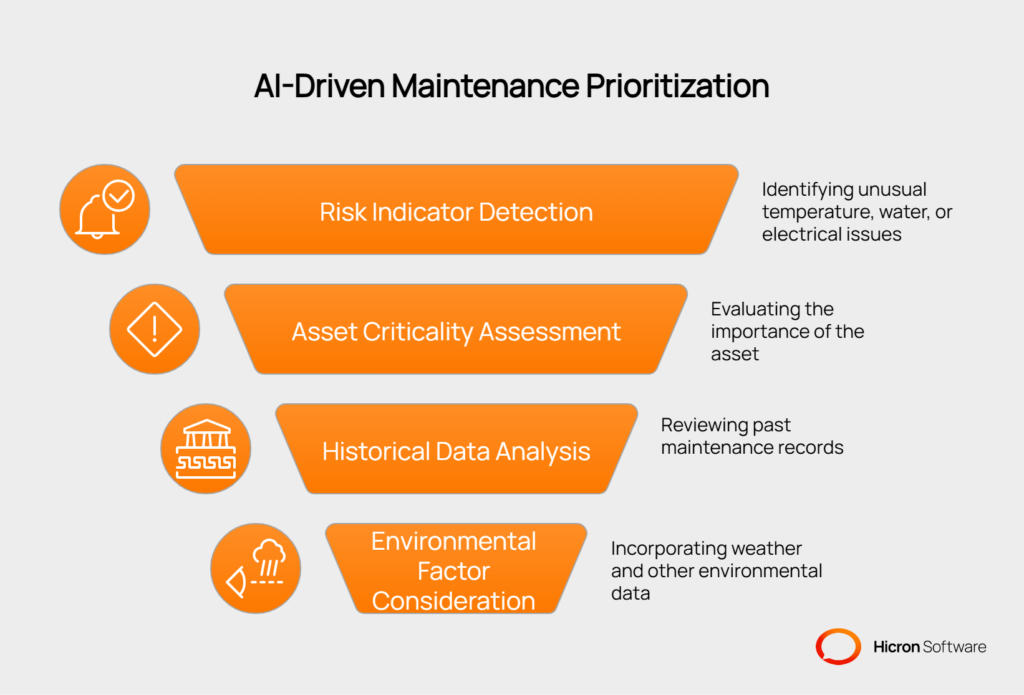

AI-driven maintenance prioritization begins with the continuous processing of real-time data from sensors and work order requests. Each alert is examined for risk indicators, such as

- unusual temperature fluctuations,

- water intrusion, or

- electrical failures.

The system considers multiple factors of asset criticality. The timing of the event, historical maintenance records, and even environmental factors such as weather are considered when assessing urgency.

In high-stakes situations, such as a sudden boiler malfunction during cold months, AI directs immediate attention from both property managers and technical teams. Lower-priority issues, like standard air filter replacements in non-essential areas, are categorized for routine scheduling.

This evaluation relies on a combination of

- predefined escalation rules,

- adaptive machine learning models, and

- continual learning from past case outcomes.

Through this method, AI accurately differentiates safety-urgent maintenance from requests that fit standard cycles. After classification, the system sends out automated notifications containing clear instructions, expected timeframes for resolution, and guidance for next steps.

This type of communication supports tenant experience enhancement by reducing resident uncertainty and downtime. It also improves operational performance through more proactive maintenance scheduling.

Read about our residential real estate software development services.

Compliance management is maintained throughout the process with detailed audit records, transparent policy checks, and structured approval pathways. By automating these workflows, property managers achieve faster emergency responses, reduce manual triage errors, and ensure tenant needs are met while satisfying regulatory obligations.

Unified dashboards for efficient multi-property work order management

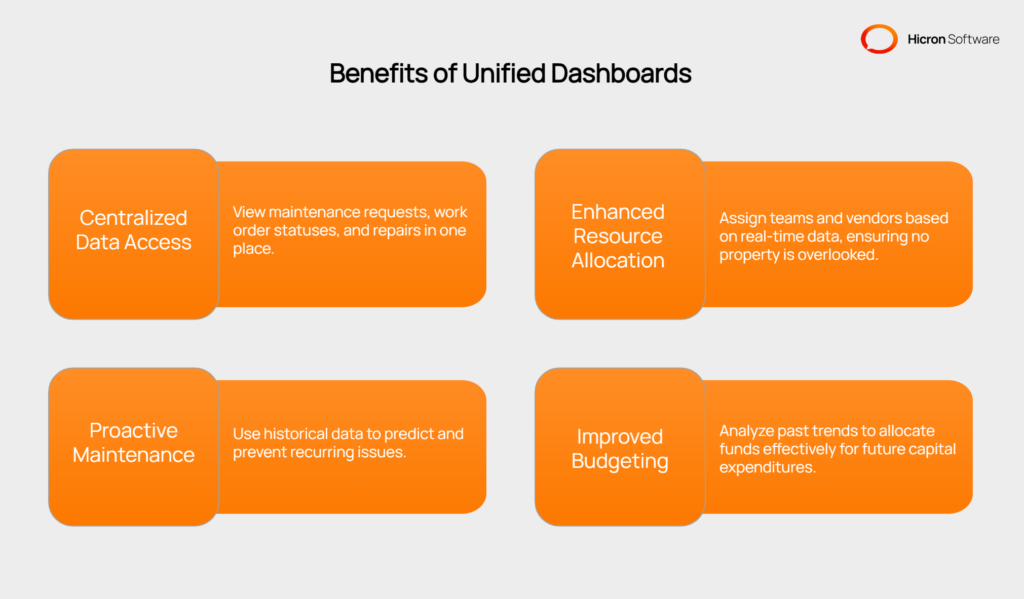

Unified dashboards provide property teams with a single view of work orders, asset health, and technician activity across all sites. Managers can compare KPIs such as response times, first-time fix rates, and open ticket aging, then drill down into a property to identify recurring issues or parts shortages.

Real-time alerts and filters help prioritize high-impact tasks, coordinate vendor schedules, and control costs with data-backed decisions. This clarity sets up the next step of refining workflows and resource allocation across the portfolio.

Check out industrial real estate software development services!

Benefits of unified dashboards in work order management

#1 Centralized data access: View tenant maintenance requests, work order statuses, and ongoing repairs in one place.

#2 Enhanced resource allocation: Assign teams and vendors based on real-time data, ensuring no property is overlooked.

#3 Proactive maintenance: Use historical data to predict and prevent recurring issues, such as HVAC failures or plumbing breakdowns.

#4 Improved budgeting: Analyze past trends to allocate funds effectively for future capital expenditures.

Technologies and development strategies for unified work order dashboards

Creating unified dashboards for efficient multi-property work order management requires a combination of modern technologies and a strategic software development approach. Here’s a breakdown of the recommended technologies and development strategies:

| Category | Recommended Technologies/Approach |

| Frontend Technologies |

|

| Backend Technologies |

|

| Database Solutions |

|

| IoT Integration |

|

| AI and Analytics |

|

| Cloud Infrastructure |

|

| Security and Compliance |

|

| Development Methodology |

|

| Real-Time Data Processing |

|

| Scalability and Performance |

|

| Testing and QA |

|

| CI/CD Pipeline |

|

How long does it take to automate preventive maintenance with IoT and AI?

The timeline for automating preventive maintenance with IoT and AI depends on the project’s complexity, the scale of implementation, and the available resources. Below is an estimated timeline broken into key phases:

| Phase | Description | Estimated Duration |

| 1. Discovery and Planning |

|

2-4 weeks |

| 2. Technology Selection |

|

2-3 weeks |

| 3. IoT Sensor Deployment |

|

4-6 weeks |

| 4. Backend Development |

|

6-8 weeks |

| 5. Dashboard and UI Development |

|

4-6 weeks |

| 6. Integration and Automation |

|

4-6 weeks |

| 7. Testing and QA |

|

3-4 weeks |

| 8. Training and Deployment |

|

2-3 weeks |

| 9. Post-Deployment Support |

|

Ongoing (first 4-6 weeks critical) |

Total estimated timeline: 4-6 months for a medium-scale implementation.

Factors that can impact the timeline:

- Project scale: Larger portfolios with multiple properties may require more time for sensor deployment and system integration.

- Complexity of AI models: Developing and training AI models for predictive maintenance can take longer if the data is complex or insufficient.

- Existing infrastructure: If the property management system is outdated, additional time may be needed for upgrades or compatibility adjustments.

- Team expertise: A skilled team with experience in IoT, AI, and software development can significantly reduce the timeline.

- Regulatory compliance: Ensuring compliance with data privacy laws (e.g., GDPR, CCPA) may add time to the planning and testing phases.

The future of automating preventive maintenance with IoT and AI

Preventive maintenance is about leveraging IoT and AI to automate preventive maintenance in work order management. These technologies are transforming property management by streamlining operations, reducing costs, and driving PropTech innovations, while also promoting sustainability in property management and investing in future-proof technology for real estate.

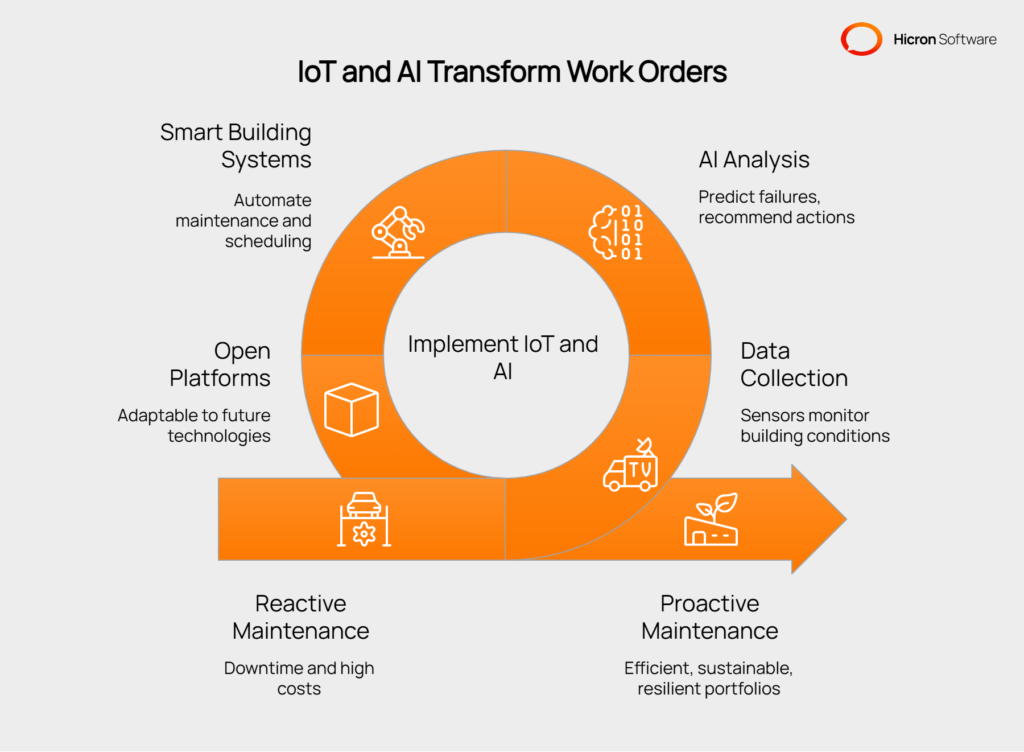

How IoT and AI are driving digital transformation in work order management?

IoT sensors installed throughout buildings continually monitor equipment conditions, energy use, and environmental factors. These devices generate a steady stream of data, giving property managers real-time insights into system health.

AI analyzes this data to detect patterns, predict failures, and recommend maintenance actions before issues escalate. This approach helps reduce equipment downtime and operational costs. It also improves efficiency across entire portfolios.

Next, innovations in PropTech are enabling the development of smart building systems that can automatically identify maintenance needs, schedule service appointments, and even verify that repairs have been completed correctly.

This level of automation helps standardize processes and reduces reliance on manual oversight. As the industry progresses, PropTech innovations will continue to introduce advanced analytics, remote monitoring tools, and machine learning models that further optimize performance.

Sustainability in Property Management is another key benefit of integrating IoT and AI. Predictive maintenance supports more efficient HVAC operation, early leak detection, and demand-based lighting controls. These improvements help lower utility usage and reduce carbon emissions, creating buildings that are more environmentally friendly and cost-effective.

Investing in open, adaptable platforms now ensures that assets can incorporate future-proof technology for the real estate sector. This allows properties to stay ahead of regulatory changes, integrate new sensors and software updates, and accommodate future advancements in predictive analytics without expensive renovations.

As IoT and AI become increasingly central to operations, property managers who embrace these trends will be better positioned to build resilient, efficient, and sustainable portfolios.

Work order management: Maximizing ROI and tenant satisfaction with smart maintenance

IoT and AI have revolutionized how property managers automate preventive maintenance in work order management, delivering key benefits such as improved ROI for property portfolios, reduced operational costs, and enhanced efficiency.

These technologies enable proactive maintenance, minimizing disruptions and creating effective tenant retention strategies by ensuring a seamless tenant experience.

As the real estate industry embraces digital transformation, adopting IoT and AI is no longer optional—it’s essential. Property managers who integrate these smart solutions can future-proof their portfolios, boost tenant satisfaction, and achieve long-term success.

If there is a need, you can check custom real estate software development services.

Start automating preventive maintenance to unlock the full potential of your properties, improve ROI, and lead the way in modern property management.

FAQ

What is preventive maintenance in work order management?

Preventive maintenance in work order management involves proactively monitoring and maintaining building systems, such as HVAC units, plumbing, and elevators, to prevent unexpected failures. This approach ensures equipment runs efficiently, reduces repair costs, minimizes downtime, and extends the lifespan of assets.

How does automating preventive maintenance work?

Automating preventive maintenance utilizes IoT sensors and AI technologies to monitor equipment in real-time, predict potential issues, and schedule maintenance tasks automatically. IoT sensors collect performance data, such as temperature, vibration, and energy usage, while AI analyzes this data to generate work orders and assign tasks to the right technicians.

What are the benefits of automating preventive maintenance?

Automating preventive maintenance offers several advantages, including:

- Improved ROI: Reduced repair costs and extended equipment lifespan.

- Enhanced tenant satisfaction: Proactive issue resolution creates a seamless experience.

- Streamlined workflows: Automated work order generation and task assignments save time.

- Energy efficiency and sustainability: IoT and AI optimize energy usage and reduce waste.

How does IoT help in preventive maintenance?

IoT (Internet of Things) refers to connected devices, such as sensors, that monitor building systems in real-time. In preventive maintenance, IoT sensors collect data on equipment performance, such as temperature, humidity, and energy usage. This data helps property managers detect inefficiencies, predict failures, and schedule maintenance before issues escalate.

How long does it take to implement IoT and AI for preventive maintenance?

The timeline for implementing IoT and AI for preventive maintenance depends on the project’s complexity and scale. On average, it takes 4-6 months for medium-scale implementations, including:

- Planning and technology selection.

- IoT sensor deployment.

- System integration and training.

What are the key technologies used in automating preventive maintenance?

Key technologies include:

- IoT sensors for real-time monitoring.

- AI-driven property insights for predictive analytics.

- Centralized property management systems for workflow automation.

- Cloud platforms for scalability and data storage.

Testimonials

Get in touch