How to Improve Your Dealership’s After-Sales Process for Better Customer Retention

- December 08

- 15 min

The automotive after-sales service sector has long been an important element of the automotive industry’s value chain, directly influencing customer satisfaction, brand loyalty, and profitability. Traditionally, this sector has operated on reactive models – where services such as predictive automotive maintenance, repairs, and part replacements are performed following customer requests or scheduled visits based on generic timelines.

This approach, while straightforward, often leads to inefficiencies such as overstocked inventories, underutilized resources, unpredictable service times, and variably satisfied customers.

Examples of such traditional practices include scheduled servicing based on mileage or time intervals, reactive automotive maintenance in response to vehicle breakdowns, and a one-size-fits-all approach to customer service that fails to recognize individual customer needs or preferences.

However, the advent of digital tools, particularly artificial intelligence (AI) and automotive predictive analytics, is ushering in a new era for automotive after-sales services.

These technologies enable a more proactive, personalized, and efficient approach to after-sales care. By analyzing vast amounts of data from vehicle sensors, customer interactions, and service history, AI and automotive predictive analytics tools can anticipate service needs before they arise.

This not only ensures better maintenance of vehicles but also allows for the optimization of inventory management, with parts being ordered and stocked based on predictive models rather than historical averages.

These digital tools for after-sales services facilitate a more customized service experience.

For example, personalized service reminders can be sent to vehicle owners based on individual driving patterns rather than generic schedules, and recommendations for additional services can be tailored to each customer’s usage profile and preferences.

This shift towards data-driven, predictive service models enhances operational efficiency for service providers and significantly improves customer satisfaction in automotive services by delivering timely, relevant, and efficient service solutions.

The integration of AI and automotive predictive analytics into automotive after-sales services represents a paradigm shift from reactive to proactive service delivery. This transformation is poised to redefine the landscape of after-sales services, offering substantial benefits to both service providers and customers alike.

Automotive after-sales services have traditionally been a linchpin of the automotive industry, directly influencing customer retention and brand loyalty. These services encompass everything from regular predictive automotive maintenance and repairs to warranty services and parts replacements.

However, the conventional strategies deployed in the management of these services are increasingly showing their limitations in the face of evolving consumer expectations and technological advancements.

#1 Manual diagnostics: Historically, diagnostics in automotive after-sales services have relied heavily on manual inspections and the expertise of technicians. While this approach benefits from the nuanced understanding of experienced professionals, it is inherently time-consuming and can lead to variability in service quality depending on the technician’s skill level.

#2 Reactive maintenance: The predominant model of maintenance within the automotive sector has been reactive, wherein servicing occurs after an issue occurs or at predetermined intervals regardless of vehicle condition. This approach often leads to underutilizing vehicle life spans and components, as maintenance schedules are not optimized for individual vehicle use cases.

#3 Scheduled servicing based on mileage or time: A common practice in automotive after-sales services is to recommend servicing based on mileage or fixed time intervals. While simple to administer, this method does not account for the varying conditions under which vehicles operate, such as differences in driving styles, environments, or load conditions.

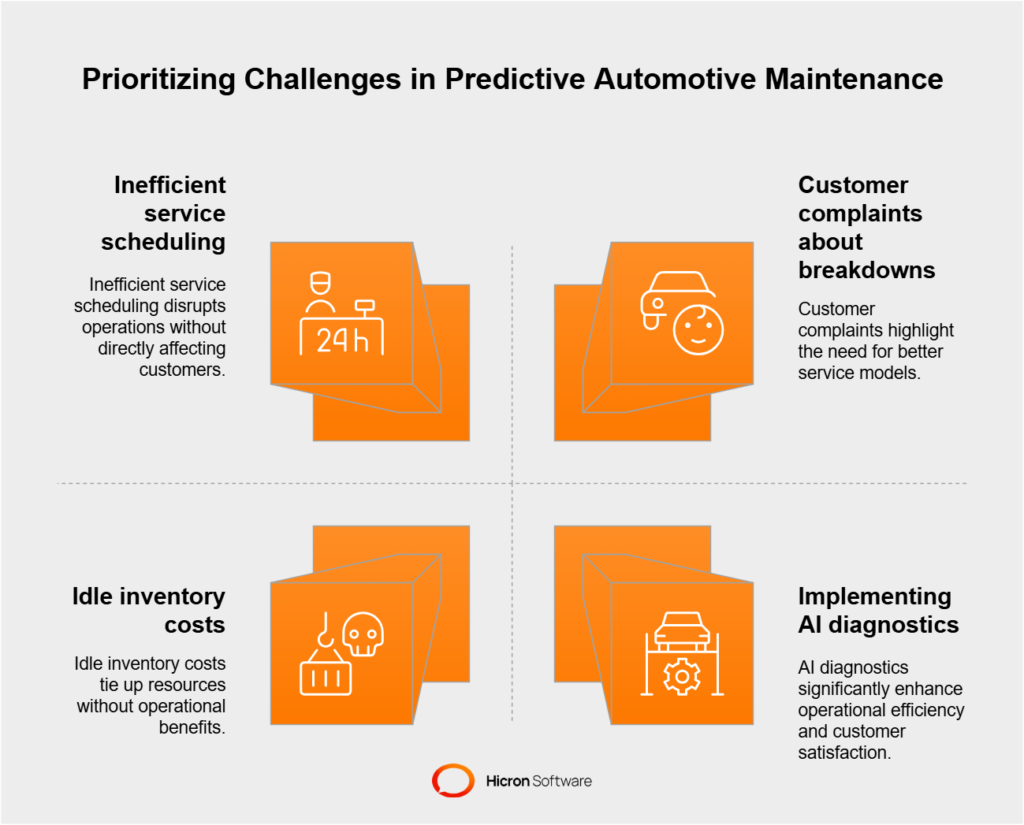

#1 High operational costs: The reliance on manual diagnostics and reactive automotive maintenance models leads to high operational costs. Inventory management becomes a significant challenge as dealerships must stock a wide range of parts to prepare for any potential repair, many of which may sit idle, tying up capital and space.

#2 Customer dissatisfaction: Unexpected breakdowns and the inconvenience of unplanned service visits can lead to significant customer dissatisfaction. The reactive maintenance model does little to mitigate these issues, as it does not prevent the occurrence of breakdowns but rather responds after the fact.

#3 Inefficiencies in service scheduling and delivery: Manual diagnostics and scheduled servicing based on broad criteria lead to inefficiencies in service scheduling, with vehicles being serviced too early or too late relative to their actual conditions. This inefficiency not only impacts the operational capacity of service centers but also affects customer satisfaction in automotive services due to the perceived lack of personalized service.

#4 Quality variability: The dependency on human diagnostics can result in variability in service automotive quality control. Misdiagnosis or oversight can lead to unnecessary repairs, repeat visits, and increased costs for both the service provider and the customer.

The need for more predictive and personalized after-sales services is evident, prompting a shift towards the adoption of advanced technologies like AI and automotive predictive analytics. These tools offer the promise of transcending the limitations of traditional after-sales service models, heralding a new era of efficiency, customer satisfaction, and operational excellence in the automotive industry.

Among technological advancements, cloud-based Customer Relationship Management (CRM) systems stand out for their ability to streamline interactions between businesses and their customers. These sophisticated platforms offer an all-encompassing solution for enhancing customer experiences, enabling businesses to foster stronger relationships with their clientele.

Cloud-based CRM systems are designed to centralize customer data, making it easily accessible to service teams from anywhere, at any time. This level of accessibility is crucial in today’s fast-paced market, where immediate response and personalization are key to customer satisfaction in automotive services.

By leveraging the power of cloud computing, businesses can ensure that their customer service representatives have real-time access to the information they need to address inquiries and resolve issues promptly.

The advent of digital tools for after-sales service has brought about transformational changes, significantly improving operational efficiency and customer satisfaction in automotive services. Two notable areas of impact are real-time inventory management and efficient service scheduling.

Digital tools for after-sales services have enabled businesses to implement real-time inventory management systems, which provide up-to-the-minute data on stock levels, order statuses, and delivery timelines.

This transparency is invaluable for both businesses and customers, as it helps to set realistic expectations and reduce the potential for dissatisfaction due to delays or stockouts. Real-time inventory management also aids in identifying trends, predicting demand, and optimizing stock levels, thus reducing overhead costs and increasing profitability.

Efficient scheduling of services is another area where digital tools have made a significant impact. With the help of advanced scheduling software, businesses can optimize their service appointments, ensuring that resources are utilized effectively, and customers are served promptly.

This software often includes features like automated reminders, online booking options, and mobile access, further enhancing the customer experience by offering convenience and flexibility.

For service-oriented businesses, this means reduced wait times, increased throughput, and higher levels of customer satisfaction in automotive services.

The adoption of digital tools for after-sales services has heralded a new era of efficiency and customer-centricity. By harnessing the capabilities of cloud-based CRM systems, real-time inventory management, and efficient scheduling software, businesses can not only meet but exceed customer expectations. This digital transformation streamlines operations and strengthens the bond between businesses and their customers, paving the way for sustained success in today’s competitive market landscape.

This concept refers to businesses’ ability to foresee and act on potential issues before they escalate, ensuring that services are delivered seamlessly and without interruption.

Predictability in after-sales services is all about anticipation and proactive measures. For instance, in the automotive industry, leveraging automotive predictive analytics to anticipate vehicle issues before they occur can significantly minimize downtime for the customer.

This approach involves analyzing data from various sources, including vehicle diagnostics, automotive maintenance history, and even real-time sensor data, to identify patterns or signs that could indicate a pending failure.

The power of predictability lies in its ability to transform the after-sales service landscape from reactive to proactive. Instead of waiting for a problem to arise, businesses can use data-driven insights to preemptively address issues. This not only enhances the reliability of the product but also instills a sense of trust and reliability in the brand.

#1 From a customer satisfaction perspective

From the perspective of customer satisfaction, predictability is invaluable. By avoiding sudden breakdowns or failures, customers enjoy a more reliable and consistent experience with their products. This reliability can be especially critical in industries where downtime translates directly to lost revenue or inconvenience, such as in transportation or manufacturing. Customers are likely to be more loyal to brands that can offer peace of mind through dependable after-sales services.

#2 From an operational efficiency perspective

Predictability also plays a vital role in optimizing operational efficiency. By identifying potential issues before they turn into actual problems, businesses can better manage their resources, including scheduling service appointments more effectively and ensuring that parts and personnel are available when and where they are needed. This foresight can lead to significant cost savings, as preventive measures are often less expensive than emergency repairs or replacements. Additionally, it allows businesses to smooth out workloads, avoiding the peaks and troughs associated with unexpected service demands.

Predictability in after-sales services offers a dual advantage. For customers, it provides a more reliable and satisfying product experience, reducing the stress and inconvenience of unexpected issues.

For businesses, it enhances operational efficiency by allowing for the strategic allocation of resources and minimizing unforeseen challenges.

By investing in automotive predictive analytics and adopting a proactive approach to service management, businesses can achieve a competitive edge, fostering both customer loyalty and operational excellence.

The integration of digital tools into after-sales services has been a game-changer in building predictability, enhancing both customer satisfaction and operational efficiency.

By leveraging advanced technologies such as automotive predictive analytics, artificial intelligence (AI), and the Internet of Things (IoT), businesses can now anticipate customer needs, forecast potential issues, and deliver personalized, proactive service solutions.

Predictive analytics stands at the forefront of this transformation, especially in sectors where reliability is important, such as the automotive industry. This technology utilizes vehicle data, including usage patterns, automotive maintenance history, and sensor data, to predict potential failures before they occur.

For instance, by analyzing engine temperatures, vibrations, and other operational metrics, predictive models can identify signs of wear and tear that may lead to breakdowns, enabling preemptive maintenance actions that prevent downtime and costly repairs.

Such predictive capabilities not only ensure that vehicles remain operational but also help in optimizing maintenance schedules. This reduces the likelihood of unexpected issues, thereby increasing customer trust and satisfaction.

Furthermore, businesses benefit from streamlined operations and reduced service costs, as predictive automotive maintenance often involves less resource expenditure than reactive maintenance.

#1 Artificial Intelligence for personalized customer interactions

By analyzing customer behavior and service history, AI can personalize communication, recommend specific maintenance actions, and even predict future service needs. This level of personalization enhances the customer experience, making interactions more relevant and timely. Additionally, AI-driven chatbots and virtual assistants provide 24/7 support, answering queries and scheduling services without human intervention, further improving service accessibility and responsiveness.

#2 Internet of Things for real-time vehicle monitoring

The IoT has revolutionized real-time vehicle monitoring, allowing for continuous tracking of vehicle performance and condition. Sensors embedded in vehicles collect data on various parameters, such as fuel efficiency, engine performance, and component health, transmitting this information to cloud-based platforms for analysis. This seamless data collection and analysis enable immediate identification of irregularities, facilitating swift action to mitigate issues before they escalate.

IoT technology also supports remote diagnostics, allowing service providers to assess a vehicle’s condition remotely and, in some cases, perform updates or repairs without needing physical access. This capability significantly enhances service efficiency and convenience, reducing the need for in-person service visits and minimizing vehicle downtime.

Technologies like predictive analytics, AI, and IoT provide a solid foundation for anticipatory service models that prioritize customer satisfaction and operational excellence.

By harnessing these digital tools for after-sales services, businesses cannot only predict and prevent potential issues but also offer a more personalized, efficient, and responsive service experience. In doing so, they set a new standard for after-sales service in the digital age, driving loyalty, reducing costs, and establishing a competitive edge in the market.

The successful incorporation of digital tools in the automotive industry demonstrates the significant benefits of leveraging technology for proactive maintenance and issue resolution. Two standout examples of such innovation are BMW’s Teleservices and Tesla’s over-the-air (OTA) updates.

These cases highlight the practical application of digital tools for after-sales services and offer valuable insights into best practices for integrating these technologies into existing processes.

#1 BMW’s use of teleservices for proactive maintenance

BMW’s Teleservices represent a pioneering approach to vehicle maintenance and customer service. By equipping vehicles with connected technology, BMW is able to remotely monitor vehicle health, including wear and tear on critical components, battery status, and service needs.

When the system identifies a potential issue or the need for routine maintenance, it automatically notifies both the owner and the nearest BMW service center, scheduling an appointment at a convenient time.

This proactive approach has several advantages. It enhances customer satisfaction by reducing the inconvenience of unexpected breakdowns and service visits, optimizes maintenance workflows, and ensures that vehicles operate at peak performance.

The key lesson from BMW’s implementation is the importance of a seamless integration between the vehicle’s onboard diagnostics and the manufacturer’s service infrastructure. This tight integration allows for real-time data exchange and immediate action, setting a high standard for customer-centric service.

#2 Tesla’s Over-the-Air updates for issue resolution

Through its use of OTA updates, Tesla has revolutionized the automotive industry’s approach to software updates and issue resolution. Unlike traditional vehicles, which require a physical visit to a service center for most updates and fixes, Tesla vehicles receive software updates remotely, much like smartphones.

These updates can enhance vehicle performance, introduce new features, and even resolve identified issues without any inconvenience to the owner.

Tesla’s OTA updates underscore the potential of digital tools for after-sales services to improve the customer experience and significantly reduce operational costs associated with physical service appointments. Furthermore, the ability to push updates to all vehicles simultaneously ensures that all customers benefit from improvements and fixes right away.

The lesson here is the power of digital tools for after-sales services to deliver continuous value and improvements post-purchase, fostering brand loyalty and customer satisfaction in automotive services.

Both BMW’s Teleservices and Tesla’s OTA updates illustrate the critical importance of seamlessly integrating digital tools with existing business processes and infrastructure. This integration enables businesses to leverage real-time data, automate service processes, and deliver a superior customer experience.

Another lesson is the commitment to continuous improvement and the willingness to innovate. By constantly seeking ways to apply new technologies, these companies stay ahead of customer expectations and emerging challenges.

Lastly, these case studies highlight the importance of a customer-centric approach. Both BMW and Tesla have used digital tools for after-sales services to improve vehicle performance and reliability and enhance the overall customer experience. This focus on the customer drives brand loyalty and sets a high standard for competitors.

The success of BMW’s Teleservices and Tesla’s OTA updates provides compelling evidence of the value of digital tools for after-sales services. The lessons learned from these implementations – seamless integration, continuous improvement, and a customer-centric focus – are invaluable for any business looking to leverage technology to enhance service offerings and customer satisfaction.

The landscape of digital after-sales services is poised for transformation as emerging technologies like augmented reality (AR), blockchain, and 5G telecommunications are increasingly integrated.

These advancements promise to redefine the standards of service delivery, customer interaction, and operational efficiency. Here’s an insightful look into how each of these technologies could shape the future of digital after-sales services.

Augmented reality is set to revolutionize the way businesses approach diagnostics and troubleshooting. By overlaying digital information onto the physical world through AR glasses or smartphone apps, technicians can visualize problems and solutions in real-time, even when they are not physically present with the vehicle or device.

This capability can enhance remote support, allowing experts to guide customers or less experienced technicians through complex repairs and maintenance tasks from anywhere in the world.

For example, in the automotive sector, AR can enable a technician to see a 3D model of a car’s engine overlaid on the actual vehicle, highlighting areas that need attention. This speeds up the diagnostic process and improves the accuracy of repairs, reducing the risk of repeat issues.

Blockchain technology, known for its security and transparency, offers significant potential for managing spare parts in after-sales service processes. By recording transactions on a decentralized ledger, blockchain can track the provenance, ownership, and lifecycle of every part with unparalleled accuracy. This transparency can drastically reduce fraud, counterfeiting, and inefficiencies in the supply chain.

Furthermore, smart contracts—self-executing contracts with the terms of the agreement directly written into code—could automate ordering and payment processes, streamlining operations and ensuring timely availability of spare parts. This would boost operational efficiency and enhance customer satisfaction by minimizing service delivery delays.

The rollout of 5G technology is expected to significantly enhance real-time data transfer capabilities. With its promise of higher speeds, lower latency, and increased connectivity, 5G could enable more sophisticated and seamless IoT applications in after-sales services. For instance, it would allow for more efficient real-time monitoring and predictive maintenance, where vast volumes of data from sensors embedded in vehicles or devices can be analyzed instantly to forecast potential failures.

The enhanced connectivity offered by 5G also opens up possibilities for more interactive and immersive customer service experiences, such as real-time AR-based support and advanced telematics services. This could further improve predictability in after-sales services, ensuring issues are identified and addressed before they escalate.

The integration of Augmented Reality, blockchain, and 5G telecommunications into the fabric of digital after-sales services heralds a new era of innovation and efficiency.

These technologies promise to enhance remote diagnostics, ensure transparent and efficient management of spare parts, and improve real-time data transfer, thereby elevating both customer satisfaction and operational effectiveness.

As businesses begin to adopt and adapt to these emerging trends, we can expect to see a significant shift in how after-sales services are delivered, with a greater emphasis on predictability, personalization, and transparency.

In the rapidly evolving automotive sector, the strategic implementation of digital tools is not just an option but a necessity for staying competitive. Here are practical steps and considerations for automotive companies looking to harness the power of digital technologies effectively.

#1 Develop in-house expertise: Build a dedicated team focused on data analytics. This includes hiring data scientists and analysts with experience in predictive analytics, machine learning, and big data technologies.

#2 Adopt advanced analytics platforms: Invest in state-of-the-art analytics software that can process large volumes of data from various sources, including vehicle sensors, customer feedback, and market trends.

#3 Training and development: Ensure continuous learning and development opportunities for staff to keep up with the latest analytics techniques and tools.

#1 Strategic alliances: Forge partnerships with leading technology firms and startups that specialize in augmented reality, IoT, blockchain, and other emerging technologies relevant to the automotive industry.

#2 Collaborative innovation: Work closely with tech partners to co-develop bespoke digital solutions that address specific challenges in after-sales services, production, or customer engagement.

#3 Pilot programs: Launch pilot projects to test new technologies and tools in real-world settings before full-scale rollouts, adjusting based on feedback and performance metrics.

The implementation of digital tools for after-sales services brings its set of challenges, notably concerning data security and privacy. Here’s how to address these concerns:

#1 Data security concerns

#2 Privacy policies

Integrating digital tools into automotive companies’ operations and services offers a pathway to enhanced efficiency, customer satisfaction, and innovation.

By investing in data analytics, partnering with tech companies, and proactively addressing challenges like data security and privacy, these companies can position themselves strongly in a digital-first future. Adopting these strategic recommendations will mitigate risks and unlock new opportunities for growth and competitiveness in the automotive industry.

Digital tools for after-sales services have become indispensable in the automotive industry, especially in enhancing the predictability of after-sales services.

Technologies such as predictive analytics, IoT, augmented reality, and blockchain have revolutionized how automotive companies approach maintenance, repairs, and customer service.

For instance, predictive analytics can foresee potential vehicle issues before they occur, allowing for proactive maintenance that considerably reduces downtime and enhances vehicle longevity. This improves customer satisfaction by ensuring reliability and safety and enhances operational efficiency by streamlining service schedules and reducing unexpected repair costs.

BMW’s Teleservices and Tesla’s over-the-air updates exemplify how digital tools can significantly impact customer satisfaction and operational efficiency. BMW’s use of connected technology for remote diagnostics and maintenance scheduling exemplifies a proactive approach to customer service.

At the same time, Tesla’s OTA updates demonstrate the efficiency and convenience of remote software upgrades and issue resolution. These examples underline the transformational impact of digital tools on automotive after-sales services.

The automotive industry’s future appears increasingly intertwined with digital transformation. The potential introduction of autonomous vehicles stands out as a significant development, promising to further reshape after-sales services.

Autonomous vehicles will likely require highly sophisticated, real-time monitoring and diagnostic capabilities to ensure safety and reliability. This could lead to an even greater reliance on digital tools and technologies, from advanced sensors and AI-driven analytics for predictive automotive maintenance to blockchain for secure and transparent documentation of vehicle history and repairs.

The evolution towards autonomous vehicles also opens up new opportunities for enhancing customer experiences and operational practices. For example, autonomous vehicles could be programmed to autonomously travel to service centers for maintenance, minimizing inconvenience for owners.

Furthermore, the data collected by these vehicles could provide invaluable insights into user behavior, vehicle performance under different conditions, and long-term wear and tear patterns, enabling manufacturers to improve vehicle design and functionality continuously.

Digital tools have already profoundly impacted the predictability and efficiency of automotive after-sales services, as illustrated by successful implementations by leading companies like BMW and Tesla.

With the ongoing digital transformation and the advent of autonomous vehicles, the industry is set to witness even more significant changes.

These developments will likely bring about new challenges but also open up unprecedented opportunities for improving service delivery, customer satisfaction, and operational efficiency. The future of automotive after-sales services will undoubtedly rely heavily on the strategic integration of digital technologies, marking a new era of innovation and customer-centricity in the industry.