Creating Unified Automotive Experience: The Role of Tailored Front-Ends

- March 05

- 14 min

In the realm of the automotive industry, the concept of Pre-Delivery Inspection (PDI) stands as a pivotal process that plays a multifaceted role in ensuring the utmost quality and reliability of vehicles before they embark on their journey into the hands of eagerly awaiting customers.

Pre-Delivery Inspection (PDI) encompasses a comprehensive examination carried out on vehicles as a final checkpoint to unearth any potential defects, damages, or discrepancies that may have arisen during the manufacturing, transit, or storage phases. This meticulous inspection aims to address and rectify any issues, thereby setting the stage for the delivery of vehicles that meet and exceed the highest standards of safety, performance, and quality.

The importance of pre-delivery inspection (PDI) reverberates throughout the automotive industry, resonating with both manufacturers and dealerships alike. By delving into the intricate details of pre-delivery inspection (PDI), it becomes evident that this process acts as a safeguard, a quality assurance mechanism that acts as a shield against the delivery of vehicles plagued by imperfections. In essence, it serves as a beacon of assurance, underlining the commitment of manufacturers and dealerships to deliver vehicles that not only meet but surpass the lofty expectations and stringent benchmarks set by customers.

One of the foremost reasons why Pre-delivery inspection (PDI) holds such paramount importance is its role in upholding the safety and reliability of vehicles. Through the rigorous scrutiny of various components, systems, and functionalities, Pre-delivery inspection ensures that every vehicle aligns with the uncompromising safety standards demanded by customers, regulators, and industry best practices. By identifying potential safety hazards and addressing them proactively, pre-delivery inspection becomes an indispensable ally in preserving the well-being and trust of customers.

In the grand narrative of customer experience, pre-delivery inspection emerges as a protagonist that significantly influences the plot. The successful execution of pre-delivery inspection fosters a ripple effect that culminates in elevated customer satisfaction and unwavering trust in the brand. By averting the delivery of defective or subpar vehicles, manufacturers and dealerships can instill confidence in their customers, cementing enduring relationships and fostering advocacy reverberating across the automotive industry.

The implementation of a robust Pre-delivery inspection (PDI) process serves as a proactive measure to mitigate potential risks and minimize warranty costs. By diligently identifying and rectifying issues prior to delivery, manufacturers and dealerships can circumvent the repercussions of post-sale defects, thereby reducing the financial burden associated with warranty claims and after-sales service.

Pre-Delivery Inspection (PDI) stands as a process within the automotive industry, guaranteeing the quality, safety, and overall reliability of vehicles before they are delivered to customers. The meticulous nature of Pre-Delivery Inspection encompasses a comprehensive examination of various components, systems, and functionalities within a vehicle to ensure that it meets and exceeds the stringent standards set forth by manufacturers and expected by customers.

The essence of Pre-Delivery Inspection manifests as a detailed and methodical procedure that revolves around meticulously inspecting both the exterior and interior of a vehicle. This inspection encompasses a holistic approach, delving into the examination of electrical parts, mechanical components, fluid levels, and accessories, if any. Through this thorough scrutiny, potential defects, damages, or discrepancies that may have arisen during the manufacturing, transit, or storage phases are brought to light and addressed proactively.

The comprehensive nature of Pre-Delivery Inspection extends beyond the mere visual inspection, encompassing a detailed examination of the vehicle’s mechanical components, such as its engine, transmission, suspension, steering, and brakes. The inspection also delves into assessing the vehicle’s electrical systems, including its lighting, instrumentation, and onboard technology. By scrutinizing these integral facets, Pre-Delivery Inspection serves as a linchpin in ensuring that every vehicle is visually appealing, functionally sound, and roadworthy.

Pre-delivery inspection reverberates in its profound impact on upholding the quality, safety, and overall reliability of vehicles. By subjecting vehicles to a rigorous PDI process, manufacturers and dealerships uphold their commitment to delivering vehicles that embody uncompromising safety standards and exemplary quality. Through the identification and rectification of potential defects or issues, Pre-Delivery Inspection acts as a safeguard, ensuring that each vehicle undergoes a stringent evaluation before it embarks on its journey into the hands of customers.

The role of Pre-Delivery Inspection embodies a commitment to excellence, safety, and customer-centricity within the automotive industry. By embracing the pivotal role of PDI, manufacturers and dealerships embark on a journey towards delivering vehicles that stand as paragons of quality, reliability, and customer confidence.

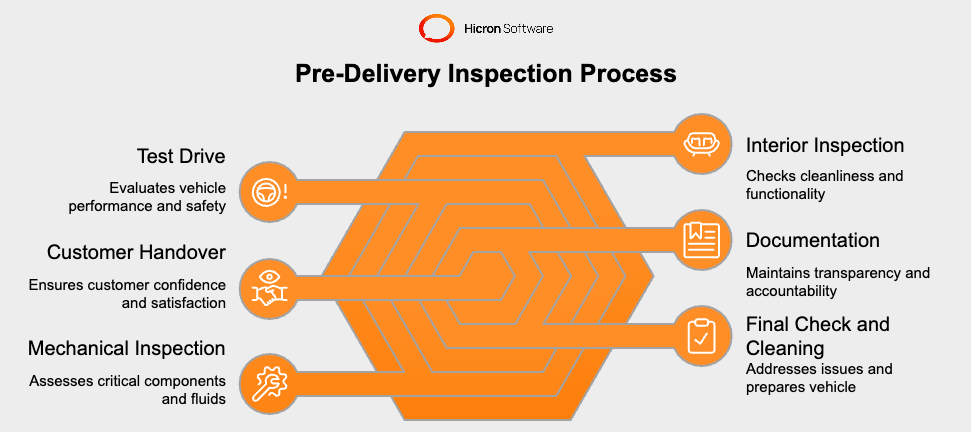

The Pre-Delivery Inspection (PDI) process is a pivotal stage in the journey of a vehicle from the manufacturer to the customer. It involves a series of meticulous steps aimed at ensuring that the vehicle is in optimal condition and meets the highest standards of quality and safety before being handed over to the customer. Let’s delve into a detailed explanation of each step involved in the PDI process and explore the significance of each step:

Upon receiving the vehicle from the manufacturer, the Pre-Delivery Inspection team initiates the process by conducting a thorough inspection to detect any damages that may have occurred during transportation. This step sets the foundation for the entire PDI process, as it allows the team to identify and address any external issues that may have arisen during transit, ensuring that the vehicle’s integrity is preserved.

The visual inspection stage involves a comprehensive scrutiny of the vehicle’s exterior. The PDI team meticulously checks for any scratches, dents, or imperfections on the bodywork. Additionally, they ensure that all lights are in proper working condition, inspect the tires for signs of wear or damage, and verify the presence of all accessories specified for the particular vehicle model. This step holds immense significance as it not only contributes to the vehicle’s aesthetic appeal but also confirms its functional integrity.

Moving to the interior, the Pre-Delivery Inspection team focuses on examining the cleanliness of the cabin area and the precise fitting of all interior components. The functionality of electronic systems such as the stereo, air conditioning, and navigation system is thoroughly tested to ensure seamless operation. This step is integral in delivering a superior customer experience, as a clean and well-functioning interior enhances the overall appeal and usability of the vehicle.

The mechanical inspection phase encompasses a detailed assessment of the vehicle’s crucial mechanical components. This includes a close examination of the engine, transmission, brakes, and other essential mechanical parts to identify any potential issues that may affect the performance or safety of the vehicle. The fluid levels, including engine oil, brake fluid, and coolant, are meticulously checked and topped up as necessary to guarantee optimal performance and safety standards.

Conducting a comprehensive test drive is a pivotal step in the Pre-Delivery Inspection process. This involves taking the vehicle on a test drive to evaluate its performance, including the responsiveness of the brakes, the precision of the steering, the smooth operation of the transmission, and the overall driving experience. During the test drive, any unusual noises or vibrations are carefully noted for further investigation. This step ensures that the vehicle delivers on its promise of a smooth and reliable driving experience for the customer.

Following the test drive, a final comprehensive check is carried out to address any issues identified during the test drive. Any anomalies or concerns discovered during the test drive are thoroughly addressed to ensure that the vehicle meets the highest standards of quality and performance. Subsequently, the vehicle undergoes meticulous cleaning, both inside and out, to present it in a pristine and appealing condition for customer delivery.

All findings from the Pre-Delivery Inspection process are meticulously documented for future reference. This documentation includes detailed records of the inspections conducted, any issues identified, and the corresponding resolutions. By maintaining comprehensive documentation, the dealership ensures transparency and accountability throughout the PDI process, allowing for traceability and continuous improvement in the inspection procedures.

As the vehicle is prepared for customer delivery, the PDI team engages in a transparent and informative handover process. They explain the comprehensive checks and inspections that have been carried out, providing the customer with detailed documentation for their records. This step ensures that the customer is fully informed about the quality and condition of their new vehicle, instilling confidence and satisfaction in their purchase.

By meticulously adhering to each step of the Pre-Delivery Inspection process, dealerships and manufacturers demonstrate their commitment to upholding the highest standards of quality, safety, and customer satisfaction. The thoroughness and attention to detail in the Pre-Delivery Inspection procedure not only ensure that the vehicle meets regulatory and quality standards but also contribute significantly to the overall customer experience and brand reputation.

How does a pre delivery inspection improve the customer experience? Pre-Delivery Inspection (PDI) plays a crucial role in shaping the customer experience and significantly influences customer satisfaction in various industries. The interaction between the customer and the service provider during the PDI process has been shown to have a profound impact on overall satisfaction. Let’s delve into a discussion on how PDI affects customer satisfaction, supported by examples and case studies that illustrate its impact on the customer experience.

The influence of cultural differences on Pre-Delivery Inspection (PDI) and customer satisfaction is a critical aspect that significantly shapes the customer’s perception and evaluation of service quality. Research findings have underscored the substantial impact of cultural nuances on customer satisfaction, emphasizing the need to recognize and adapt PDI processes to align with diverse cultural perspectives.

Cultural disparities have been identified as influential factors that can affect customer satisfaction by influencing the interpretation of service encounters. The joint effect of consumer and service providers’ culture has emerged as a pivotal determinant of overall satisfaction in various service settings. Adapting PDI processes to resonate with diverse cultural perspectives presents an opportunity to enhance customer satisfaction and positively influence the customer experience.

Understanding and acknowledging cultural differences in the context of PDI is instrumental in fostering an environment where customers from varied cultural backgrounds feel valued and understood. By tailoring PDI processes to accommodate diverse cultural perspectives, businesses can demonstrate their commitment to providing a customer-centric experience that respects and reflects the cultural diversity of their clientele.

This approach not only contributes to enhancing customer satisfaction but also fosters an inclusive and empathetic customer experience, ultimately strengthening the relationship between the service provider and the customer.

In the realm of cross-border e-commerce, the influence of cultural values on customer satisfaction has garnered significant attention. Academic studies have shed light on the profound impact of cultural values on shaping customer satisfaction, emphasizing the necessity for tailored Pre-Delivery Inspection (PDI) processes that consider and accommodate cultural nuances, particularly in the context of cross-border transactions.

The distinct cultural values held by consumers in different regions play a pivotal role in determining their expectations and perceptions of service quality. Recognizing and addressing these cultural disparities through customized PDI processes can effectively contribute to ensuring high levels of customer satisfaction in cross-border e-commerce scenarios.

By incorporating an understanding of cultural values into the Pre-Delivery Inspection procedure, businesses engaged in cross-border e-commerce can proactively mitigate potential misunderstandings or dissatisfaction arising from cultural differences. This proactive approach serves to align the service delivery with the diverse cultural expectations of customers, thereby fostering an environment conducive to elevated customer satisfaction and positive customer experiences.

The integration of tailored Pre-Delivery Inspection processes that account for cultural nuances in cross-border e-commerce transactions serves as a testament to a customer-centric approach that respects and adapts to the diverse cultural fabric of the global consumer base. Ultimately, this approach not only bolsters customer satisfaction but also contributes to building trust and loyalty among customers engaged in cross-border e-commerce interactions.

Studies have suggested that the justice dimension of service recovery plays a substantial role in influencing customer satisfaction. This highlights the critical importance of Pre-Delivery Inspection (PDI) in ensuring that any issues or concerns are addressed transparently and fairly, thereby contributing to a positive service recovery experience and ultimately bolstering customer satisfaction.

The concept of justice in service recovery encompasses various dimensions such as perceived fairness, equity, and procedural justice, all of which have been found to significantly impact customer satisfaction following a service failure. When customers perceive that their concerns are being addressed in a just and equitable manner, it can lead to a restoration of trust, an enhanced perception of service quality, and ultimately, greater satisfaction with the overall service experience.

Incorporating the principles of justice into the Pre-Delivery Inspection process is crucial for businesses aiming to mitigate the negative effects of service failures and actively engage in effective service recovery. By embracing fairness and transparency in addressing customer concerns, businesses can demonstrate a commitment to upholding the rights and expectations of their customers, thereby fostering an environment conducive to heightened customer satisfaction and loyalty.

Furthermore, understanding the nuanced dimensions of justice in service recovery can inform the development of proactive strategies aimed at preempting potential issues and effectively addressing customer concerns, thereby contributing to the creation of a robust service recovery framework that positively impacts customer satisfaction.

A case study conducted by Pre-Delivery Inspection Technologies showcased the impact of Pre-Delivery Inspection on customer satisfaction. The study presented a real-world example of how a robust Pre-Delivery Inspection process led to higher customer satisfaction, underscoring the tangible benefits of prioritizing thorough pre-delivery inspections.

By considering the influence of cultural differences, the significance of service quality in cross-border transactions, and the impact of justice in service recovery, it becomes evident that Pre-Delivery Inspection plays a pivotal role in shaping customer satisfaction. These examples and case studies provide compelling evidence of the profound impact of Pre-Delivery Inspection on the overall customer experience, highlighting the necessity of a meticulous and customer-centric approach to pre-delivery inspections.

The Pre-Delivery Inspection (PDI) process is a pivotal stage in the journey of a vehicle from the manufacturer to the customer. It involves a series of meticulous steps aimed at ensuring that the vehicle is in optimal condition and meets the highest standards of quality and safety before being handed over to the customer. Let’s delve into a detailed explanation of each step involved in the PDI process and explore the significance of each step.

#1 Limited time and resources

The Pre-Delivery Inspection (PDI) process often grapples with the challenge of limited time and resources, primarily due to the high volume of vehicles requiring inspection and the subsequent strain on available manpower. The demand for Pre-Delivery Inspection often outpaces the available resources, leading to a scenario where there is insufficient manpower to carry out thorough inspections within the allocated timeframes. As a result, time constraints can force technicians to conduct rushed inspections, potentially compromising the comprehensiveness and accuracy of the process. This confluence of limited time and resources underscores the need for strategic resource allocation and efficient workflow management to uphold the integrity of the Pre-Delivery Inspection process.

#2 Inadequate training

The lack of proper training for Pre-Delivery Inspection (PDI) personnel presents a significant challenge within the automotive industry. Without adequate training and certification, inspectors may face difficulties in interpreting and implementing inspection guidelines effectively. This can result in misinterpretation or misunderstanding of crucial inspection protocols, potentially leading to overlooked issues or inconsistent assessment practices. It is imperative that PDI personnel receive comprehensive training and ongoing professional development to ensure a thorough understanding of inspection guidelines, thereby upholding the integrity of the PDI process and promoting consistent, high-quality inspections.

#3 Logistics and coordination

The logistics and coordination aspects within the Pre-Delivery Inspection (PDI) process are often fraught with challenges, particularly in coordinating between different departments involved in the PDI workflow. The seamless management of vehicle flow from the receiving area to the final delivery stage poses a significant logistical challenge, necessitating efficient coordination and communication among various departments.

The complexity of the Pre-Delivery Inspection process, involving multiple checkpoints and stages, demands meticulous coordination among departments such as receiving, inspection, maintenance, and delivery. Issues related to bottlenecks, delays, or miscommunication can arise, impacting the smooth flow of vehicles through each stage of the PDI process.

Efficiently managing the flow of vehicles from when they are received for inspection to their eventual delivery to customers is essential for maintaining operational efficiency and meeting customer delivery expectations. Addressing these challenges requires strategic planning, streamlined communication channels, and the implementation of efficient logistical solutions to ensure a seamless PDI procedure.

#4 Technological challenges

The Pre-Delivery Inspection (PDI) process faces several technological challenges that impact its efficiency and effectiveness. One such challenge is the presence of inadequate or outdated tools and technology for conducting and documenting inspections. This inadequacy can hinder the ability to perform thorough and accurate inspections, potentially leading to oversight of critical issues.

Moreover, integrating new technologies into the PDI process presents its own set of challenges. The adoption of advanced inspection tools, automated systems, and digital documentation methods may encounter resistance or difficulties in implementation. Ensuring seamless integration and optimizing new technologies within the Pre-Delivery Inspection workflow requires careful planning, training, and a phased approach to mitigate potential disruptions and maximize the benefits of technological advancements.

Addressing these technological challenges is crucial for enhancing the accuracy, speed, and comprehensiveness of the PDI procedure, ultimately contributing to improved customer satisfaction and operational efficiency.

#5 Quality control

In the realm of quality control, inconsistencies can arise in the quality of inspections due to human error. The subjective nature of certain inspection criteria and the reliance on individual judgment can lead to variations in assessments, impacting the overall consistency and reliability of the inspection process.

Moreover, maintaining high standards throughout the entire inspection process presents its own set of challenges. From initial assessment to final review, ensuring that rigorous quality standards are upheld at every stage demands meticulous attention to detail, standardized protocols, and ongoing training to equip inspectors with the necessary skills and knowledge.

Addressing these inherent challenges in quality control is crucial for enhancing the integrity and efficacy of inspection processes, ultimately contributing to the delivery of high-quality products and services to customers.

#6 Communication issues

The Pre-Delivery Inspection (PDI) process encounters challenges in effectively communicating any identified issues to the relevant parties. Whether it’s relaying inspection findings to the maintenance team for necessary repairs or communicating critical issues to upper management for decision-making, ensuring clear and concise communication poses a significant challenge.

Furthermore, conveying the results of the Pre-Delivery Inspection to customers in a clear and understandable manner presents its own set of difficulties. Translating technical inspection reports into customer-friendly language, effectively conveying the severity of identified issues, and providing transparent information to customers without causing undue alarm requires a delicate balance and a high level of communication proficiency.

Addressing these communication challenges is pivotal for fostering transparency, maintaining trust, and ultimately delivering a positive customer experience throughout the PDI process.

#7 Documentation and record-keeping

Accurately documenting the findings of inspections presents a significant challenge within the inspection process. Ensuring that all pertinent information is captured, recorded, and organized in a consistent manner demands attention to detail and a standardized approach to documentation. The potential for errors or omissions in recording crucial inspection findings adds complexity to maintaining the integrity of inspection records.

Additionally, managing and retrieving inspection records for future reference poses its own set of difficulties. As the volume of inspection records grows, organizing, storing, and efficiently retrieving specific records becomes increasingly challenging. Implementing effective systems for record management and retrieval is essential for preserving the accuracy and completeness of inspection records over time.

Addressing these challenges in documentation and record keeping is fundamental for fostering transparency, regulatory compliance, and informed decision-making based on historical inspection data.

To ensure a thorough and effective Pre-Delivery Inspection (PDI), addressing the inherent challenges in the process is important. Here are strategies to overcome these challenges:

The landscape of Pre-Delivery Inspections (PDI) has been significantly transformed by technological advancements, fundamentally changing how data are collected, analyzed, and shared. These innovations have streamlined the PDI process, enhancing both efficiency and accuracy.

Technological evolution has introduced pre-delivery inspection software and automated tools and systems that facilitate more thorough inspections and quality control measures. For instance, digital platforms and IoT (Internet of Things) integrations enable real-time data capture and analysis directly from field operations, laboratories, and greenhouses. This seamless data flow not only speeds up the inspection process but also improves the precision of data collected, minimizing human error.

Moreover, the advent of specialized software solutions has revolutionized data stewardship from collection to analysis. These platforms support the comprehensive management of data, ensuring quality assurance and control throughout the PDI process. The integration of such technologies into everyday PDI activities has significantly enhanced the capability to process and analyze large volumes of data efficiently.

Accurate and timely reporting is a cornerstone of the PDI process. It ensures accountability and maintains the integrity of the inspection outcomes. Technological advances have facilitated the development of reporting tools that can automatically generate detailed and understandable reports. These reports are crucial for decision-making, providing stakeholders with clear insights into the inspection findings and any necessary corrective actions.

To ensure the smooth transfer of information from PDI to other relevant parties, well-designed applications play a pivotal role. These applications offer platforms for effective communication and data sharing, bridging the gap between inspectors, management, and customers.

Pre-delivery inspection software not only streamlines the dissemination of information but also enables the customization of data presentation according to the needs of different stakeholders. As a result, they support a transparent and inclusive approach to sharing PDI outcomes, fostering trust and collaboration among all parties involved.

So, technological advancements have profoundly impacted the PDI process, from enhancing data collection and analysis to improving the efficiency of information transfer. The implementation of digital tools and well-designed applications has elevated the standards of reporting, ensuring that the PDI process remains thorough, accurate, and accountable in the digital age.

The seamless integration of PDI technologies is important for companies aiming to maintain a competitive edge, improve operational efficiency, and ensure data consistency across all platforms.

A Vehicle Management System (VMS) serves as a compelling example of how back-end systems can be leveraged to create custom applications, particularly for processes related to PDI technologies. VMS, at its core, manages critical information about vehicles, from inventory management to sales tracking and customer interactions. By integrating PDI with a VMS, businesses can unlock a new level of precision, efficiency, and customization.

The integration process involves leveraging VMS’s robust capabilities as a foundation upon which custom applications dedicated to managing product data can be built. Such custom applications are designed to address specific business needs, ranging from automating data entry to enhancing data accuracy and facilitating real-time updates across systems. This tailored approach ensures that businesses can manage their product data more effectively, leading to improved decision-making, optimized inventory management, and enhanced customer satisfaction.

However, achieving successful integration requires a deep understanding of both VMS and the intricacies of custom solutions. Hicron is a knowledgeable partner in both domains, offering a comprehensive understanding of VMS capabilities and a proven track record in developing custom solutions tailored to unique business requirements. The company’s holistic approach ensures that the integration of PDI technologies with existing systems is not only seamless but also maximizes the potential benefits for the business.

Hicron’s expertise encompasses the entire process, from initial consultation and system assessment to the development and implementation of custom applications. By partnering with us, businesses can rest assured that they are leveraging the full potential of their VMS.

The need for integration with existing systems cannot be overstated. It is a bigstep for businesses aiming to optimize their operations and enhance their competitive advantage. With our deep knowledge of both VMS and custom solutions, businesses can achieve a seamless and effective integration, unlocking new levels of efficiency, accuracy, and customer satisfaction.

Learn more about the topic, reading a real case: Smart car configuration management

Enhancing the Pre-Delivery Inspection (PDI) process is pivotal for businesses aiming to boost customer satisfaction and ensure the delivery of high-quality, safe vehicles. To achieve this, companies must embrace technological advancements that streamline the Pre-Delivery Inspection procedure, making it more efficient and reducing the margin for error through automated tools and digital reporting systems. The implementation of a standardized set of procedures across all inspections ensures consistency and maintains high-quality standards, which are important for customer trust.

Investing in the continuous training and upskilling of inspectors is another key aspect. Equipping them with the latest knowledge and tools enables them to perform thorough inspections, ensuring vehicles meet the required safety and quality standards before delivery. Furthermore, enhancing communication channels among all stakeholders involved in the PDI process, including service managers, inspectors, and customers, promotes transparency and builds trust. This open line of communication is essential for keeping customers informed and involved in the process.

Incorporating mechanisms to gather and analyze customer feedback post-delivery provides valuable insights into the effectiveness of the Pre-Delivery Inspection process and areas that require improvement. Addressing these insights not only enhances customer satisfaction but also contributes to refining the overall inspection process. Additionally, integrating quality control measures throughout the Pre-Delivery Inspection process helps in identifying and rectifying issues early, minimizing the risk of delivering vehicles with defects.

Adopting a customer-centric approach, where decisions and improvements are guided by the goal of enhancing customer satisfaction, is important. This approach ensures that the Pre-Delivery Inspection process not only meets but exceeds customer expectations, fostering long-term loyalty and trust.

By focusing on these strategies, businesses can significantly improve their Pre-Delivery Inspection process, leading to the delivery of vehicles that are not only of high quality and safe but also meet the evolving needs and expectations of customers.