Automotive Spare Parts Management: A Critical Aspect of After-Sales Processes

- February 14

- 18 min

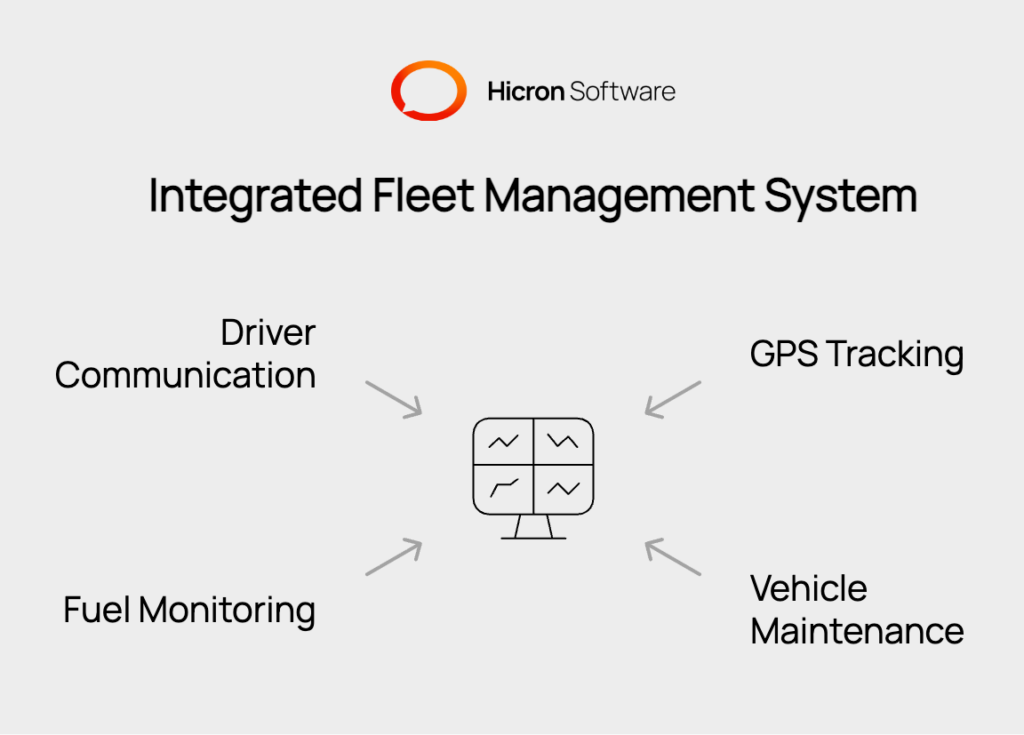

Software integration solutions for fleet management combine multiple fleet-related systems into one unified platform. These solutions connect GPS tracking, maintenance schedules, fuel management, and driver communication tools to create a single dashboard for better fleet oversight.

This article explores how these integration solutions work, their benefits, and how to choose the right one for your business. You’ll also learn about custom integration options and best practices for implementation.

Key Takeaways

Software integration solutions for fleet management are platforms that connect different fleet-related systems into one central hub. Instead of using separate tools for GPS tracking, vehicle maintenance, fuel monitoring, and driver communication, these integrated solutions create a single point of control.

The core purpose of integrated fleet management is to eliminate data silos. When your GPS system doesn’t talk to your maintenance software, you miss opportunities to optimize routes based on vehicle health. When fuel data stays separate from route planning, you can’t make informed decisions about cost efficiency.

Auto integrate fleet management takes this concept further. Integrated fleet managemnet systems automatically sync data between different platforms without manual input. When a driver completes a delivery route, the system updates mileage records in the maintenance module and adjusts fuel consumption tracking without manual intervention.

Modern integration platforms use APIs (Application Programming Interfaces) to enable communication between different software systems. This creates continuous data flow that updates across all connected platforms in real time. Fleet managers can access comprehensive

from one interface that binds together multiple applications.

Fleet management software connects with various business systems to create a smooth workflow across your organization. The most common integrations include ERP systems, CRM tools, and accounting software.

|

Integration Type |

Description |

Key Benefits |

|

ERP Systems |

Fleet data flows directly into resource planning system, automatically updating inventory levels and production schedules when deliveries are completed |

|

|

CRM Tools |

Connects fleet operations with customer service, enabling automatic customer notifications for delays and real-time vehicle location access |

|

|

Accounting Software |

Fuel purchases, maintenance costs, and driver expenses automatically appear in accounting system with proper categorization |

|

|

Warehouse Management Systems |

Automatically generates loading instructions and updates inventory when delivery trucks arrive at warehouses |

|

ERP integration allows your fleet data to flow directly into your resource planning system. When a delivery is completed, the information automatically updates inventory levels and production schedules. This eliminates the need for manual data entry and reduces errors.

CRM integration connects fleet operations with customer service. When a driver encounters a delay, the system can automatically notify affected customers and update delivery windows. Customer service representatives can access real-time vehicle locations to provide accurate updates without calling dispatch.

Accounting software integration streamlines financial processes. Fuel purchases, maintenance costs, and driver expenses automatically appear in your accounting system with proper categorization. This saves hours of manual bookkeeping and provides accurate cost tracking for each vehicle.

The integration also works with warehouse management systems. When a delivery truck arrives at a warehouse, the system can automatically generate loading instructions and update inventory systems. This coordination reduces waiting times and improves overall efficiency.

When evaluating software integration solutions for fleet management, certain features are essential for successful implementation and long-term value.

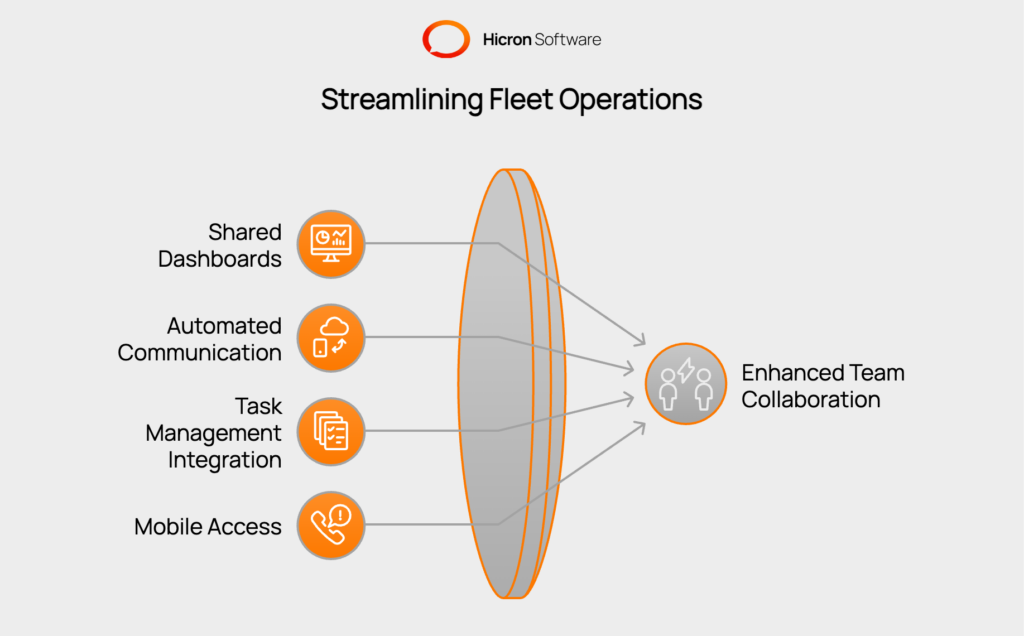

Integrated fleet management software creates better team collaboration by providing shared access to real-time information and automated communication tools.

The integration also enables better problem-solving through shared data access. When a customer complains about late deliveries, customer service can immediately check vehicle locations, traffic conditions, and driver status without contacting multiple departments.

Integrated fleet management software offers numerous advantages that improve both operational efficiency and cost management.

Improved operational efficiency comes from eliminating duplicate data entry and reducing manual processes. When systems share information automatically, employees spend less time on administrative tasks and more time on value-adding activities. Route optimization becomes more effective when the system considers

Real-time data sharing enables faster decision-making. Managers can respond immediately to breakdowns, traffic delays, or customer requests. It is because they have access to current information across all systems. This responsiveness improves customer satisfaction and reduces operational disruptions.

Cost savings result from better resource optimization and reduced administrative overhead. Integrated systems help identify

The automatic data flow reduces the need for manual data entry positions while improving accuracy.

Enhanced compliance monitoring becomes possible when all relevant data flows into one system.

can be monitored comprehensively. Automated alerts prevent violations before they occur, avoiding fines and legal issues.

Better inventory management occurs when fleet operations connect with warehouse and procurement systems. The integration can automatically reorder parts based on vehicle maintenance schedules or adjust delivery schedules based on inventory levels.

Customer service improvements result from better visibility into operations. Customer service representatives can provide

without making multiple system checks.

Implementing fleet management software integration presents several challenges that require careful planning and execution.

|

Challenge |

Description |

Best Practice |

Recommended Actions |

|

Data Migration |

Moving historical data from multiple systems into an integrated platform while maintaining information accuracy and completeness |

Structured Migration Planning |

|

|

User Training Complexity |

Employees must learn new workflows that span multiple business functions, creating training challenges across departments |

Role-Specific Training Programs |

|

|

System Compatibility Issues |

Older business software may not integrate easily with modern fleet management platforms, causing connection failures |

Thorough Compatibility Testing |

|

|

Operational Disruption Risk |

Full-scale implementation can disrupt entire operations if problems occur during deployment |

Pilot Program Implementation |

|

|

Incomplete Requirement Gathering |

Missing critical requirements from different departments can lead to integration gaps and user dissatisfaction |

Comprehensive Stakeholder Involvement |

|

|

Data Conflicts and Inconsistencies |

Multiple systems may have conflicting information, creating confusion about which data source is authoritative |

Clear Data Governance Policies |

|

|

Complex Ongoing Maintenance |

Integrated systems require coordinated updates and maintenance across multiple components and vendors |

Proactive Maintenance Planning |

|

This table pairs common implementation challenges with corresponding best practices and specific recommended actions for successful fleet management software integration.

Data migration represents one of the biggest hurdles. Moving historical data from multiple systems into an integrated platform requires careful mapping to ensure information accuracy. Create a detailed migration plan that includes data validation steps and backup procedures.

User training becomes more complex with integrated systems. Employees must learn new workflows that span multiple business functions. Develop role-specific training programs that focus on how integration affects each user’s daily tasks rather than trying to teach the entire system to everyone.

System compatibility issues can arise when older business software doesn’t integrate easily with modern fleet management platforms. Conduct thorough compatibility testing before implementation and have backup integration methods ready if primary connections fail.

Best practices for successful implementation include starting with a pilot program. Choose a small group of vehicles and users to test the integration before full deployment. This approach allows you to identify and resolve issues without disrupting entire operations.

Involve stakeholders from all affected departments in the planning process. IT staff understand technical requirements, but operations managers understand workflow needs. Customer service representatives know what information customers request most frequently.

Establish clear data governance policies before implementation. Decide which system serves as the master source for each type of data and create procedures for handling conflicts when systems disagree.

Plan for ongoing maintenance and updates. Integrated systems require more coordination when updating individual components. Establish relationships with all software vendors and create update schedules that minimize disruption.

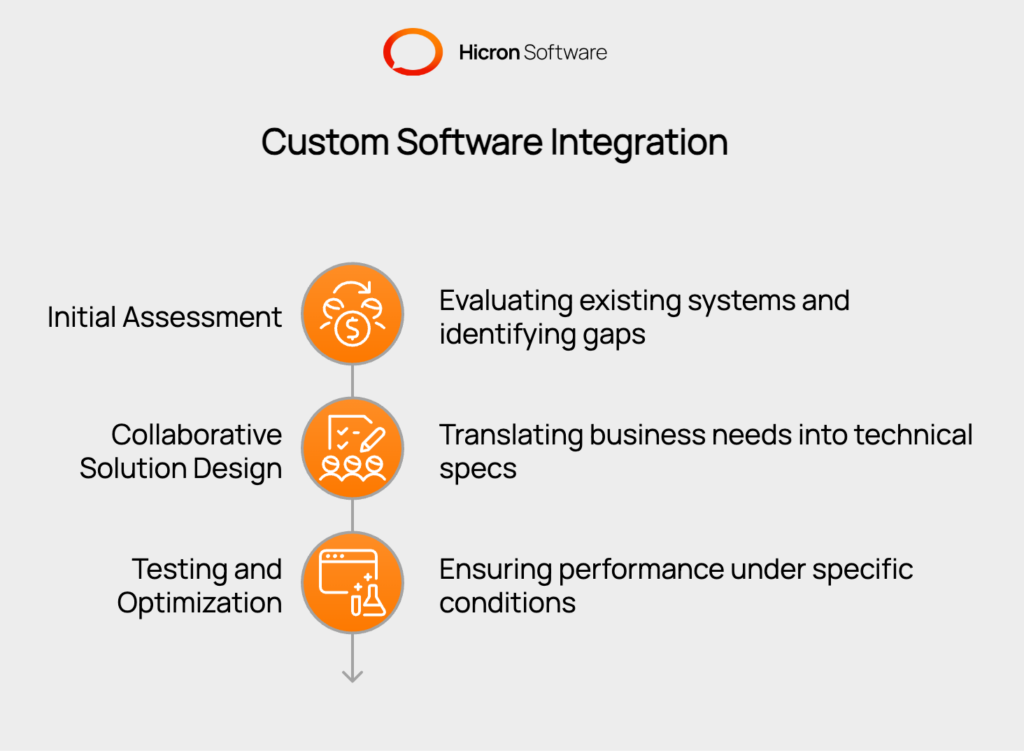

Custom software integration solutions for fleet management become necessary when off-the-shelf options don’t meet your specific business requirements. While standard integrations work for many companies, businesses with unique processes or specialized equipment often need tailored solutions.

Working with a tech partner provides access to specialized expertise in both fleet management and system integration. These partners understand the complexities of connecting different software platforms and can design solutions that address your specific challenges.

1. Initial Assessment

The development process typically begins with a comprehensive assessment of your current systems and business processes. The tech partner:

This assessment reveals gaps in current processes and opportunities for improvement.

2. Collaborative Solution Design

Collaboration on solution design ensures the final product meets your operational needs:

3. Testing and Optimization

Testing and optimization phases are crucial for custom integrations:

Custom integration solutions come with several disadvantages.

Higher Initial Costs

Longer Development Time

Longer development time means delayed benefits. While standard integrations can be implemented quickly, custom solutions may take months to develop and test. This delay can impact operations if current systems are causing major inefficiencies.

Tech Partner Dependence

Dependence on the tech partner creates ongoing risks. If the partner becomes unavailable or changes focus, maintaining and updating the custom solution becomes difficult. Choose partners with established track records and clear support commitments.

Increased Maintenance Complexity

Maintenance complexity increases with custom solutions. Standard software receives regular updates and patches from vendors. Custom integrations require dedicated maintenance resources and specialized knowledge to keep systems running smoothly.

Before pursuing custom integration solutions for fleet management, carefully weigh:

Every business operates differently, and successful fleet management integration must account for these unique requirements. Tailoring software integration solutions for fleet management ensures the system supports rather than hinders your specific operational processes.

Understanding your unique business needs starts with a thorough analysis of current workflows.

Industry-specific requirements often drive customization needs. Construction fleets need integration with project management systems to track equipment deployment. Food delivery services require temperature monitoring integration with route optimization. Medical transport fleets must connect with patient management systems while maintaining HIPAA compliance.

Modular add-ons provide flexibility without full custom development. Many integration platforms offer industry-specific modules that address common customization needs. These pre-built components cost less than custom development while providing specialized functionality.

API integrations allow you to connect with specialized software that standard integrations don’t support. If your business uses unique

API connections can bridge these gaps without replacing existing software.

User-defined workflows let you customize how the system handles different scenarios. You can

Geographic considerations affect integration needs. Multi-location operations require

International operations add currency conversion, customs integration, and country-specific reporting requirements.

Scalability planning ensures your customized solution grows with your business. Design integration architecture that can handle

without major redesign.

Future-proofing considerations include choosing integration platforms that update regularly and maintain compatibility with evolving business software. Technology changes rapidly, and your integration solution must adapt to new tools and requirements. Contact us to discuss your integration needs.

Basic fleet management software typically focuses on single functions like GPS tracking or maintenance scheduling. Integrated solutions connect multiple fleet-related systems and business processes into one unified platform, allowing data to flow automatically between different tools and departments.

Implementation time varies based on system complexity and customization needs. Standard integrations with common business software usually take 4-8 weeks. Custom integrations can take 3-6 months or longer depending on the scope of development and testing required.

Most modern integration platforms offer pre-built connectors for popular ERP, CRM, and accounting systems. If your business uses specialized software, look for solutions that provide flexible APIs for custom connections. Compatibility testing is essential before final selection.

Ongoing costs include software licensing fees, technical support, system maintenance, and periodic updates. Custom integrations may require additional development resources for major updates. Cloud-based solutions typically include maintenance in subscription fees, while on-premise systems require dedicated IT resources.

Small businesses should focus on cloud-based solutions with pre-built integrations that require minimal technical expertise. Start with basic integrations between your most-used systems and expand gradually. Many vendors offer implementation support and training specifically designed for smaller organizations with limited IT staff.