How system integration in retail solves issues with inventory management

- June 25

- 5 min

Vertical integration in system integration connects unrelated subsystems into a cohesive functional unit where components enhance each other’s value. This approach builds specialized “silos” where different elements work together within a specific business function rather than spanning the entire organization. The result? A tightly integrated system that tackles narrowly defined business needs with remarkable efficiency.

Unlike broader approaches, vertical integration dives deep rather than wide, creating specialized technology stacks that excel at particular tasks. This strategy proves especially valuable when companies need to fine-tune specific processes without necessarily linking them to every other system in their digital ecosystem.

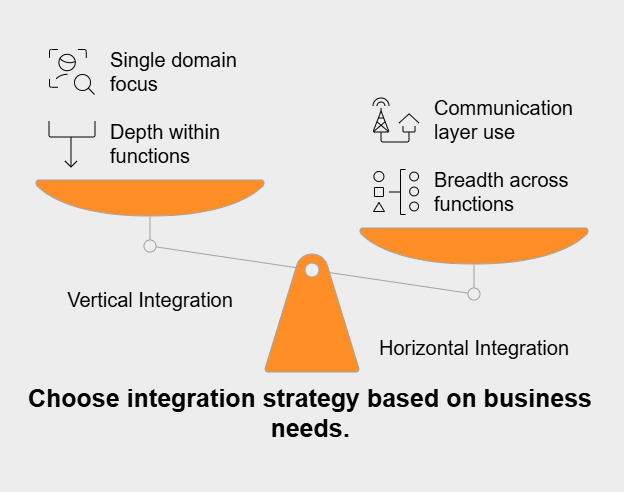

The key distinction between vertical and horizontal integration boils down to their architectural approach and scope:

In vertically integrated systems, data typically lives in one place without coordinating with other silos, creating highly specialized functionality for particular business needs. Horizontal integration, meanwhile, establishes an application layer that enables programmatic connections between diverse systems across the organization, facilitating broader data sharing and process coordination. The “silo” metaphor perfectly captures vertical integration’s structure. Just as grain silos store specific crops separately, vertically integrated systems maintain distinct data repositories and processes for specific business functions. Each silo operates relatively independently, with components working efficiently within that specific domain but with minimal interaction with other business areas.

Vertical integration in system integration exhibits several distinctive characteristics that shape its implementation and effectiveness. It typically begins as a relatively simple and fast integration method involving a limited number of vendors, partners, and developers. The initial implementation often tackles core functional requirements within a specific business domain. As needs evolve, the vertical integration expands to incorporate new functions and capabilities, growing deeper within its specialized area rather than broader across the organization.

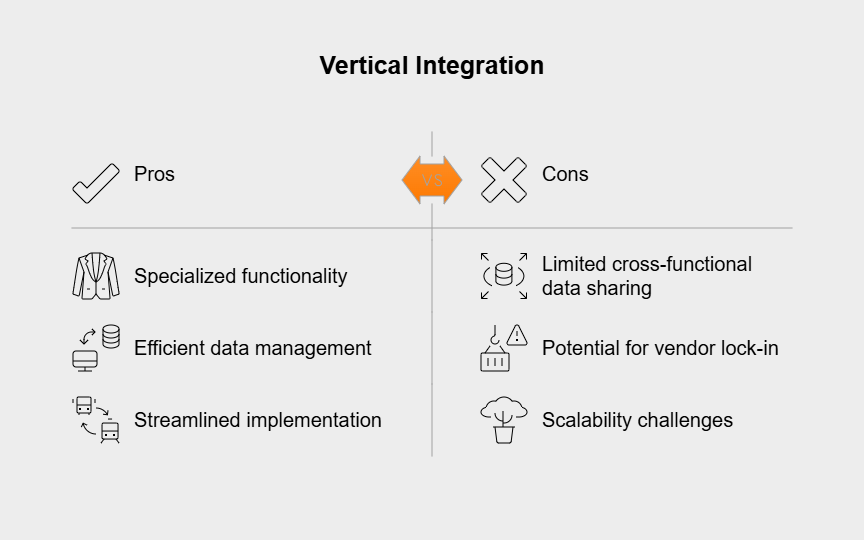

The vertically integrated system shines at delivering specialized functionality tailored to specific business requirements. Rather than trying to be a jack-of-all-trades, it focuses on mastering one domain. This specialization enables optimizations and efficiencies that might be impossible in more generalized systems. In these systems, data typically resides within the silo without extensive coordination with other business areas. This centralized data management within the functional domain enables efficient processing and analysis specific to that business function but may create hurdles when cross-functional data sharing becomes necessary.

A perfect example of vertical integration can be found in healthcare radiology systems. In this domain, two specialized systems work together to create a vertically integrated solution:

This vertical integration creates a specialized silo that holds radiology data and manages radiology workflows without necessarily coordinating with other departmental systems. The integration goes deep rather than broad, focusing on excellence within the radiology domain instead of connections to every other hospital system.

Healthcare organizations typically implement this vertical integration for radiology while using other integration approaches for cross-departmental needs, showing how different integration strategies can coexist within the same organization based on specific requirements.

Vertical integration offers several compelling advantages that make it attractive for specific business functions. The integrated nature of vertically aligned systems enables smoother coordination across related processes within a specific business function. By connecting previously unrelated subsystems into a cohesive unit, organizations can streamline workflows and reduce friction points in the process chain. This integration cuts delays, minimizes manual handoffs, and creates more predictable outcomes within the specialized domain.

With fewer interfaces between systems, communication with technology vendors becomes more straightforward. Organizations can work with a smaller, more focused set of vendors who deeply understand the specific business domain. This simplified vendor landscape reduces coordination overhead and fosters more productive partnerships focused on domain-specific optimization rather than broad integration challenges.

Vertical integration lets organizations respond more quickly to specific business needs within the silo’s domain. The specialized nature of the integration allows for rapid adaptation and optimization of critical business processes without waiting for enterprise-wide changes. This agility can create significant competitive advantages, particularly in areas where specialized functionality drives business value.

Companies maintain tighter control over the integrated processes within the vertical stack. With all components working together in a coordinated fashion within a specific domain, organizations can implement more precise governance, monitoring, and optimization. This enhanced control enables more consistent performance and better risk management within the specialized business function.

The specialized nature of vertical integration often leads to cost efficiencies within the specific business function. By optimizing processes, reducing manual interventions, and streamlining workflows within the domain, organizations can achieve significant operational savings. These efficiencies stem from the deep integration and specialization rather than from broad standardization across diverse functions.

Despite its benefits, vertical integration comes with several important limitations that organizations must consider. The silo-based nature of vertical integration can create obstacles when business processes need to span multiple functional areas. Data and processes contained within one vertical silo may not easily connect with those in another, potentially creating inefficiencies or information gaps in cross-functional workflows. Organizations often need to implement additional integration approaches to address these cross-silo requirements.

Vertically integrated systems may struggle when scaling to accommodate growing business needs. The specialized nature of the integration can make it difficult to expand beyond the original scope without significant rework. As business requirements evolve, organizations may find that the initial vertical integration approach becomes limiting rather than enabling.

When multiple vertical silos exist within an organization, there’s a risk of duplicating data, functionality, and infrastructure across different business domains. This redundancy can drive up costs and create consistency challenges when the same information exists in multiple places. Without careful governance, vertical integration can lead to an inefficient proliferation of similar capabilities across different silos.

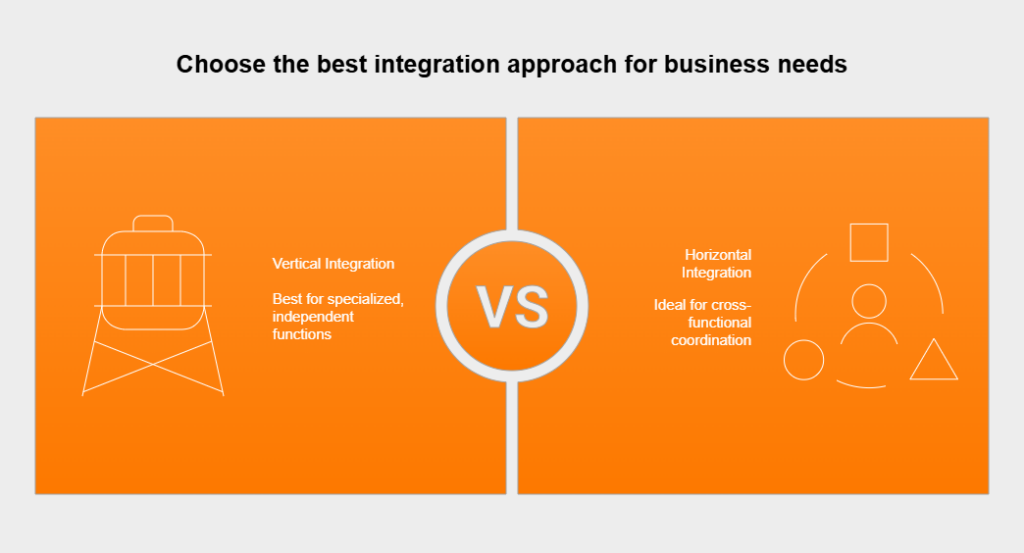

Vertical integration is particularly well-suited for specific scenarios where its characteristics align with business requirements. When a business function requires deep specialization and optimization, vertical integration often provides the best approach. Functions with unique requirements, specialized workflows, or domain-specific data models can benefit significantly from the focused integration that vertical approaches provide. Examples include specialized manufacturing processes, complex financial operations, or domain-specific healthcare functions like radiology.

Vertical integration works best when the business function has relatively limited needs for data exchange or process coordination with other functional areas. When a business domain can operate relatively independently, the silo approach of vertical integration creates fewer challenges. Organizations should evaluate the cross-functional dependencies before committing to a purely vertical approach.

When speed of implementation is critical, vertical integration often provides advantages. By focusing on a specific business domain rather than enterprise-wide integration, organizations can implement solutions more quickly and realize business value sooner. This focused approach reduces complexity and coordination requirements, enabling faster deployment and time-to-value.

Many organizations find that the most effective system integration strategy involves a thoughtful combination of vertical and horizontal approaches. Vertical integration excels at creating deep, specialized functionality within specific business domains, while horizontal integration provides the connections needed for cross-functional processes. By implementing vertical integration for critical specialized functions and horizontal integration for cross-domain needs, organizations can optimize both depth and breadth in their system architecture.

This hybrid approach allows organizations to benefit from the specialization and efficiency of vertical integration while addressing its limitations through complementary horizontal integration. The key to success lies in thoughtful architecture that determines which functions benefit most from vertical approaches and which require horizontal connections.

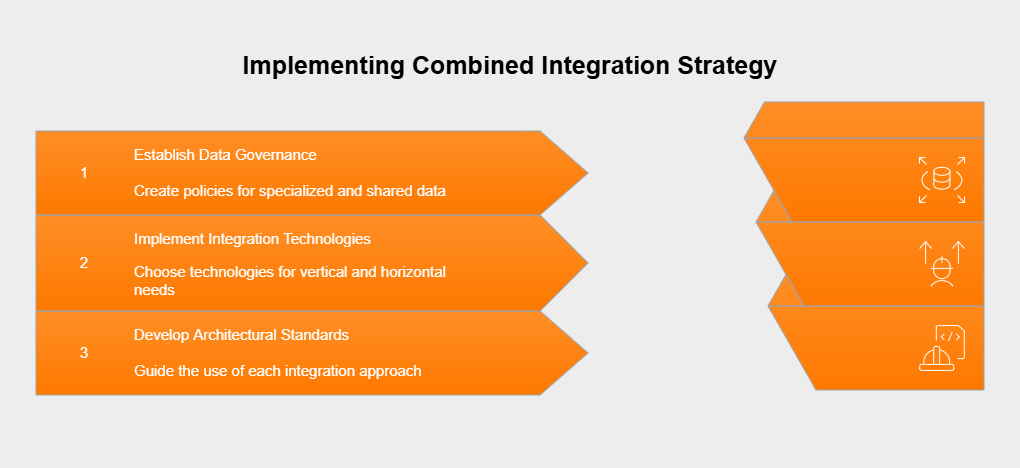

When implementing a combined vertical and horizontal integration strategy, organizations should consider several key factors:

By thoughtfully addressing these considerations, organizations can create a balanced integration strategy that leverages the strengths of both vertical and horizontal approaches while mitigating their respective limitations.