Why should automotive IT companies be TISAX compliant?

- September 23

- 9 min

The role of custom buyback software in optimizing the vehicle buyback program is exceedingly important. Vehicle buybacks play an important role in the automotive industry for several reasons.

They help maintain brand loyalty and customer satisfaction by offering consumers an option to sell their used vehicles back to the manufacturer or dealer at a predetermined price. This provides customers with a hassle-free way of disposing of their old vehicle and ensures a steady supply of used cars for resale, allowing manufacturers and dealers to control the quality and pricing of used vehicles in the market. Vehicle buyback programs can also be used as a strategic tool to manage excess inventory and mitigate risks associated with residual value losses.

However, managing vehicle buyback programs can pose several challenges for manufacturers and importers. One major challenge is predicting the future residual value of vehicles accurately. This requires complex data analysis and forecasting models, taking into account factors like market trends, economic conditions, vehicle condition, and mileage. Another challenge is the logistical complexity involved in inspecting, refurbishing, and reselling used vehicles.

From an IT perspective, this requires robust buyback software for tracking and managing vehicle data, coordinating inspections and repairs, and facilitating transactions. Additionally, regulatory compliance is another hurdle, as different regions have varying laws and regulations related to vehicle buybacks. Ensuring compliance requires a comprehensive understanding of these rules and the ability to adapt processes and systems accordingly.

A vehicle buyback, often termed as a manufacturer buyback, is a process within the automotive industry where the original car manufacturer or dealer repurchases a vehicle from the owner. This typically occurs when a car has been identified to have recurring issues that could not be resolved after multiple attempts at repair, rendering it a so-called “lemon.”

However, vehicle buyback programs aren’t always due to faulty vehicles; they can also be a part of a strategic business model aimed at maintaining a quality used-car inventory or as a customer service gesture to retain loyalty and enhance brand reputation. In such cases, the manufacturer buys back the car from the customer at a predetermined price, refurbishes it if necessary, and then re-introduces it into the market. This process ensures a degree of control over the quality and pricing of used vehicles in the marketplace, thereby providing an additional avenue for revenue and customer satisfaction.

Vehicle buyback programs play a significant role in the automotive industry, particularly in terms of customer satisfaction and brand reputation. When manufacturers offer buybacks, they demonstrate their commitment to quality and customer service. This can significantly enhance their reputation and foster greater customer loyalty.

Vehicle buyback programs also act as a safety net for customers, providing them with peace of mind knowing that they have an option if they encounter persistent issues with their vehicle. This can lead to higher customer satisfaction levels, which in turn can positively impact a manufacturer’s bottom line.

Buybacks allow manufacturers to control the quality of used vehicles in the market, as they can refurbish and resell these vehicles, ensuring they meet the brand’s standards.

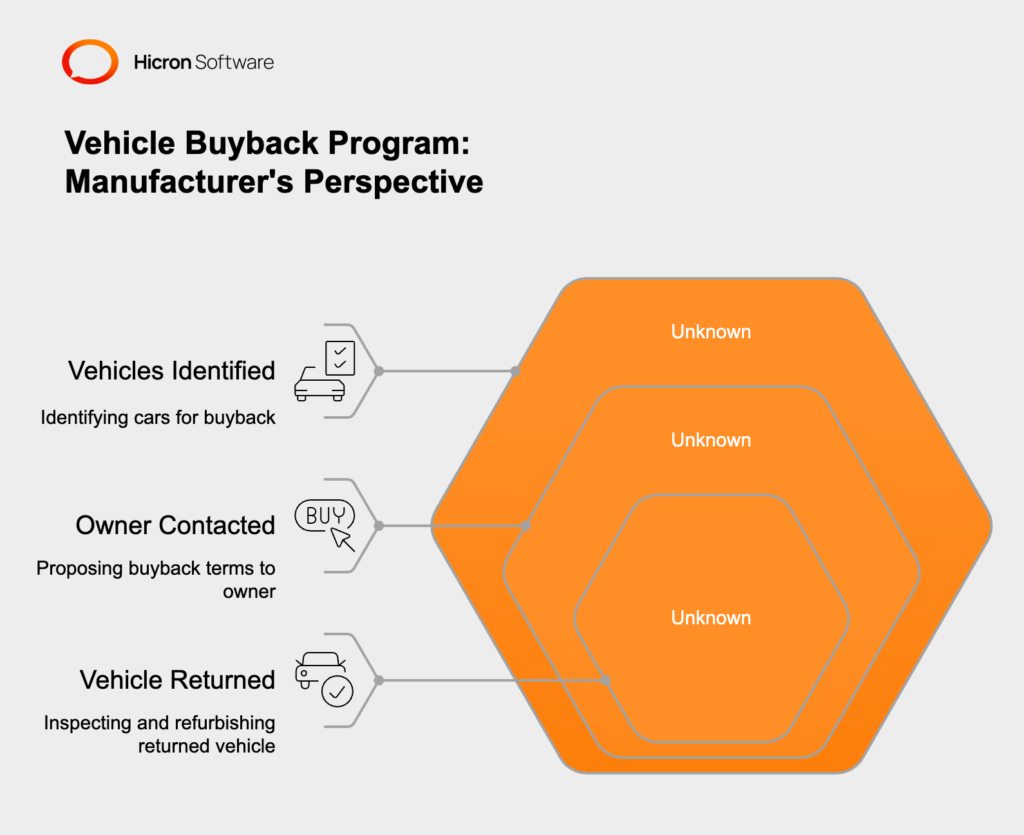

The vehicle buyback program from a manufacturer or importer’s perspective is an intricate procedure requiring careful planning, customer service, and legal compliance. It begins with identifying vehicles that qualify for buyback. These typically include vehicles with recurring issues, or “lemons,” and cars that are part of a strategic business decision aimed at managing used-car inventory or maintaining customer loyalty.

Once a vehicle is identified for a buyback program, the manufacturer contacts the owner to propose a buyback. The conditions usually involve a predetermined price based on factors like the vehicle’s age, mileage, condition, and the current market value. In some cases, a vehicle can be repurchased as a gesture of goodwill by the manufacturer to resolve a customer’s dissatisfaction, even if there’s no evidence of a real problem.

After the owner agrees to the vehicle buyback, the manufacturer arranges for the vehicle’s return and conducts a thorough inspection. If necessary, they refurbish the car to ensure it meets their quality standards before it’s re-introduced into the market. This step is critical as it protects the brand’s reputation in the used car market and reassures potential buyers about the vehicle’s quality.

Legal requirements also play a significant role in the vehicle buyback program. Manufacturers must disclose certain information, including the reason for the buyback, repairs made, and the vehicle’s warranty coverage. Some regions also require manufacturers to brand the title of the car to notify potential buyers of its history.

The buyback process from a manufacturer or importer’s perspective involves a balance of strategic planning, customer service, legal compliance, and quality control. It’s a critical tool for maintaining customer satisfaction, controlling the quality of used car inventories, and enhancing brand reputation.

A manufacturer can opt for a car buyback as a strategic business decision or an act of goodwill towards a customer.

One common condition in the buyback process is the vehicle’s warranty status. Typically, manufacturer buybacks are issued if the car is under warranty, which means the manufacturer is legally obligated to repair the vehicle. If the vehicle cannot be repaired despite numerous attempts, the manufacturer may initiate a buyback.

Other scenarios include:

From a legal perspective, manufacturers need to adhere to various requirements throughout the car buyback process. For example, they must disclose certain information to the customer, including the reason for the buyback, the repairs made on the vehicle, and the vehicle’s warranty coverage. They must also ensure compliance with regional laws that may require the branding of the title of buyback vehicles to inform potential buyers about the vehicle’s history.

Manufacturers need to navigate legal restrictions on the vehicle buyback programs to ensure a legally sound and compliant transaction. This could involve adhering to trading volume restrictions or complying with specific disclosure rules, as required by regulatory bodies like the Securities and Exchange Commission (SEC) for share repurchases.

Managing vehicle buyback programs, specifically in the automotive industry, can be a complex process with several challenges. These relate to tracking vehicle condition, accurately calculating buyback value, and ensuring legal compliance.

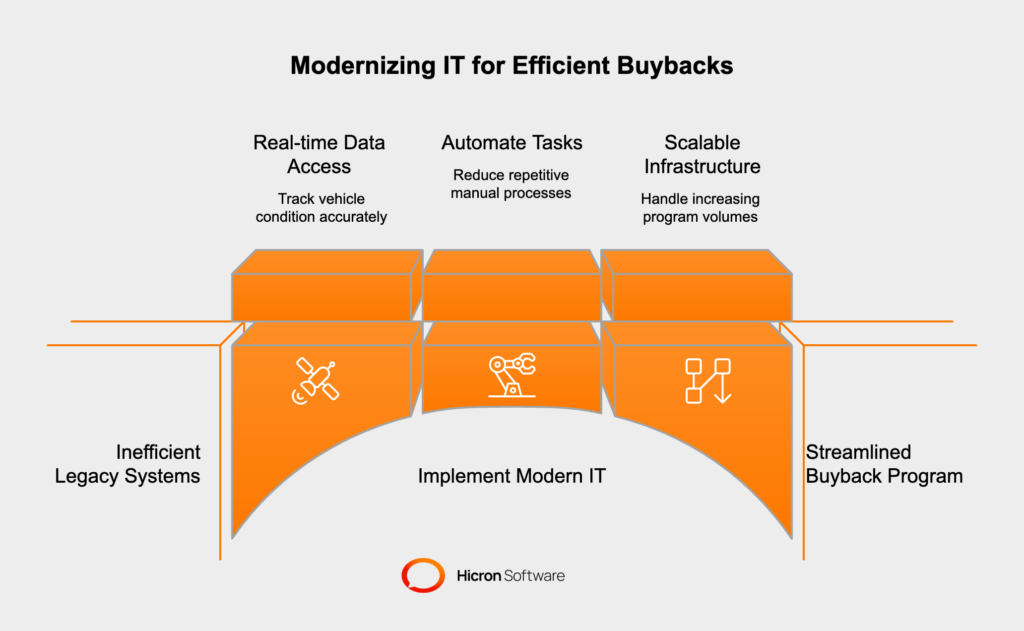

Traditional IT infrastructures often struggle to manage the complexities of the automotive buyback program due to several factors. Firstly, these systems may lack the ability to access and analyze real-time data, which is crucial for tracking the vehicle’s condition and accurately calculating its current market value.

Secondly, traditional IT systems might not be equipped to handle the multi-faceted nature of the vehicle buyback program, including managing data from multiple sources, automating repetitive tasks, or generating detailed reports to aid decision-making. This can lead to inefficiencies and errors in the process.

Finally, scalability can be a significant issue. As the volume of a vehicle buyback program increases, traditional IT systems may struggle to scale up their operations efficiently, resulting in slower processing times and increased errors. In essence, the rigid and outdated structure of traditional IT infrastructures can make them ill-suited to handle the dynamic and complex nature of the buyback process.

Explore: The Rise & Impact of the Agency Model in the Automotive Industry

Leveraging technology, especially buyback software, can significantly streamline the buyback program in the automotive industry. At the heart of this digital transformation is the concept of a software-defined infrastructure (SDI), which enables automation and enhances efficiency.

A software-defined infrastructure is an IT approach where the control of networking, storage, and computing infrastructure is automated and managed by intelligent software rather than the hardware components of a system1. In the context of buybacks, this could mean using software to automatically track vehicle conditions, calculate buyback values, ensure legal compliance, and manage data efficiently. The use of SDI can lead to more accurate and timely decisions, reduced errors, and improved scalability.

Custom applications that can communicate with Vehicle Management Systems (VMS) backend are another technological solution that can optimize buyback management. VMS is a comprehensive solution for managing all aspects of the vehicle lifecycle, including buybacks. By creating custom applications that can interface with VMS, businesses can tailor the system to their specific needs.

These custom applications can pull real-time data from the VMS, analyze it, and provide actionable insights. For example, these apps could automate the calculation of buyback value based on real-time market conditions or help manage the logistics of vehicle return and refurbishment. They could also ensure legal compliance by keeping track of relevant laws and regulations and alerting the necessary parties when a buyback is initiated.

Leveraging technology, specifically through software-defined infrastructures and custom applications integrated with VMS, can significantly enhance the efficiency and effectiveness of buyback management in the automotive industry.

More on this topic: Streamlining Buybacks: The Intersection of Custom Software and VMS for Business Objectives

Creating a custom application to manage the vehicle buyback program that can seamlessly integrate with the Vehicle Management System (VMS) backend involves several steps and key roles, such as a Business Analyst and an expert in VMS. Here’s a step-by-step guide:

See a case study: Optimizing Quality Control of After-Sales Prosess in the Automotive

Effectively managing buybacks is crucial in the automotive industry. It not only ensures a smooth experience for customers but also aids in maintaining the value of returned vehicles, thus impacting the bottom line positively. Traditional IT infrastructures may struggle to keep up with the complexities and dynamic nature of the buyback process. However, leveraging technology, specifically custom software, can significantly enhance the efficiency and effectiveness of buyback management.

Custom buyback software that integrates seamlessly with systems like Vehicle Management System (VMS) backend can automate various aspects of the buyback process, including tracking vehicle condition, calculating buyback value, ensuring legal compliance, and managing customer communications. This level of automation reduces the chances of errors, speeds up the process, and allows for more accurate and timely decisions.

For manufacturers and importers, investing in custom software for buyback management is not merely a luxury; it’s a necessity for staying competitive in today’s fast-paced market. It’s an investment that can yield significant returns in terms of improved efficiency, customer satisfaction, and profitability.

In conclusion, the digital transformation of the car buyback process through custom software is an opportunity that manufacturers and importers should consider. It presents a chance to turn a complex, often cumbersome process into a streamlined, efficient operation that benefits both the business and its customers. To discuss further, get in touch!

Vehicle buyback programs are essential tools for manufacturers and dealers as they directly contribute to enhanced brand loyalty and customer satisfaction. By offering customers a clear, hassle-free way to sell their used vehicles back at a predetermined price, these programs simplify the selling process and strengthen trust between the customer and the brand. Buyback programs allow manufacturers and dealers to maintain control over the quality and pricing of used vehicles in the market. Through refurbishment and resale, they can ensure that their vehicles remain competitive while upholding brand standards. Buyback programs serve as a strategic solution for managing excess inventory, reducing risks associated with residual value losses, and even supporting promotional campaigns or environmental initiatives focused on upgrading to greener models.

Managing vehicle buyback programs can present several complex challenges for manufacturers. One of the key issues is predicting the residual value of vehicles accurately, which involves analyzing numerous variables such as market trends, economic conditions, and the vehicle’s condition and mileage. This requires advanced data analytics and forecasting capabilities. Another challenge lies in handling the logistical complexities involved in inspecting, refurbishing, and reselling returned vehicles, all of which require seamless coordination. Legal compliance further complicates the process, as manufacturers must adhere to varying regional regulations that govern buybacks, including titling and disclosure requirements. Many manufacturers also face limitations with traditional IT systems, which often lack the flexibility, real-time data capabilities, and scalability needed to manage the dynamic nature of buyback programs effectively.

Custom buyback software plays a pivotal role in improving the efficiency and accuracy of vehicle buyback programs by bringing automation and advanced functionalities to the process. This software can streamline operations by automating tasks such as vehicle tracking, buyback value calculations, and inspections. By leveraging real-time data, it provides manufacturers with critical insights, enabling faster and more precise decisions about buyback feasibility and pricing. Custom buyback software ensures legal compliance by automating adherence to regulatory requirements and integrating tools to monitor and align with legal standards. It also enhances the customer experience by managing communication more effectively, offering features like automated updates about the status of the buyback and portals for tracking progress. Ultimately, custom buyback software reduces errors, improves decision-making, and supports smoother, more scalable operations.

Technology serves as a critical enabler for ensuring legal compliance in vehicle buyback programs. By leveraging advanced software solutions, manufacturers can automate compliance checks, reducing the likelihood of human errors in following regulatory procedures. These systems can monitor and update regional laws related to buybacks, ensuring that all processes, such as vehicle inspections, titling, and disclosure requirements, align with local regulations. Technology allows for the creation of detailed, well-documented records of every step in the buyback process, providing transparency that reinforces customer trust and meets regulatory standards. By integrating legal compliance directly into the framework of their systems, manufacturers can streamline processes, save time, and avoid potential penalties.

A strategic buyback and a lemon law buyback differ fundamentally in their purpose and execution. A strategic buyback is part of a manufacturer’s business strategy, aimed at achieving goals such as controlling the quality of their used vehicles, managing inventories, or supporting promotional campaigns. These buybacks are typically unrelated to defects and are often used as tools to maintain customer loyalty or encourage upgrades to newer, more environmentally-friendly models. On the other hand, a lemon law buyback is a legally mandated process designed to protect consumers. This occurs when a vehicle has recurring issues that cannot be resolved after multiple repair attempts, failing to meet warranty standards. Lemon law buybacks are initiated to compensate customers for defective vehicles that do not meet performance or quality expectations, ensuring consumer rights are upheld.

Custom applications can seamlessly integrate with Vehicle Management Systems (VMS) to optimize buyback management by adding tailored functionality and automating various processes. These applications can pull real-time data from VMS to monitor vehicle conditions, assess market trends, and calculate buyback values with greater precision. They also enhance logistics by coordinating vehicle inspections, returns, and refurbishments efficiently. By automating repetitive tasks, such as determining buyback value based on current market dynamics, custom applications streamline workflows and reduce manual errors. They can bolster legal compliance by keeping track of ongoing regulatory requirements and triggering alerts for necessary actions. Through tailored integration, custom applications enable businesses to scale operations, improve efficiency, and offer a better overall experience for customers and stakeholders alike.