How to Make Compliance Easier in Automotive

- May 30

- 11 min

Defining KPI for automotive dealership is crucial for tracking performance, optimizing operations, and driving sales growth effectively. The automotive industry is undergoing a significant digital transformation, revolutionizing how vehicles are designed, manufactured, and serviced. This transformation is driven by advancements in technology, changing consumer expectations, and an increasing focus on sustainability. From connected cars to autonomous driving, the integration of digital solutions is reshaping the landscape of the automotive sector.

As the automotive industry evolves, so too must the automotive aftersales service sector. Traditional methods of servicing and maintaining vehicles are becoming obsolete. Customers now expect efficient, and personalized services that leverage digital tools and data analytics. Adapting aftersales services to meet these demands is crucial for maintaining customer satisfaction, optimizing operational efficiency, and staying competitive in a rapidly changing market.

By understanding and implementing KPIs and processes, automotive businesses can enhance their aftersales service strategies, ensuring they are well-equipped to meet the challenges and opportunities presented by the digital age.

The impact of digital transformation on automotive aftersales service is profound, significantly altering how automotive businesses manage and deliver their services. Digital transformation in aftersales service involves the adoption of advanced technologies and digital tools to streamline operations, improve customer satisfaction, and enhance overall efficiency. This encompasses everything from predictive maintenance using IoT sensors to personalized customer interactions facilitated by AI-driven platforms.

The definition and scope of digital transformation in aftersales service extend beyond merely implementing new technologies. It includes a fundamental shift in business processes, organizational culture, and customer engagement strategies. Digital transformation aims to create a more interconnected and responsive service ecosystem, where data-driven insights and automation play crucial roles in decision-making and operational processes.

The benefits of digital tools and technologies for aftersales operations are extensive. By leveraging digital solutions, businesses can achieve higher levels of precision and efficiency. For instance, predictive analytics can anticipate maintenance needs before issues arise, reducing downtime and improving vehicle longevity. Digital platforms enable seamless communication with customers, offering real-time updates and personalized services that enhance customer loyalty and satisfaction. Additionally, automation reduces manual workloads, allowing staff to focus on more complex tasks and strategic initiatives.

However, the journey toward digital transformation is not without its challenges. One of the key challenges is the integration of legacy systems with new digital solutions, which can be complex and costly. Data security and privacy concerns also need to be addressed, especially given the increased reliance on data-driven processes. Despite these challenges, the opportunities presented by digital advancements are vast. Businesses that successfully navigate the digital landscape can unlock new revenue streams, improve operational efficiency, and offer superior customer experiences.

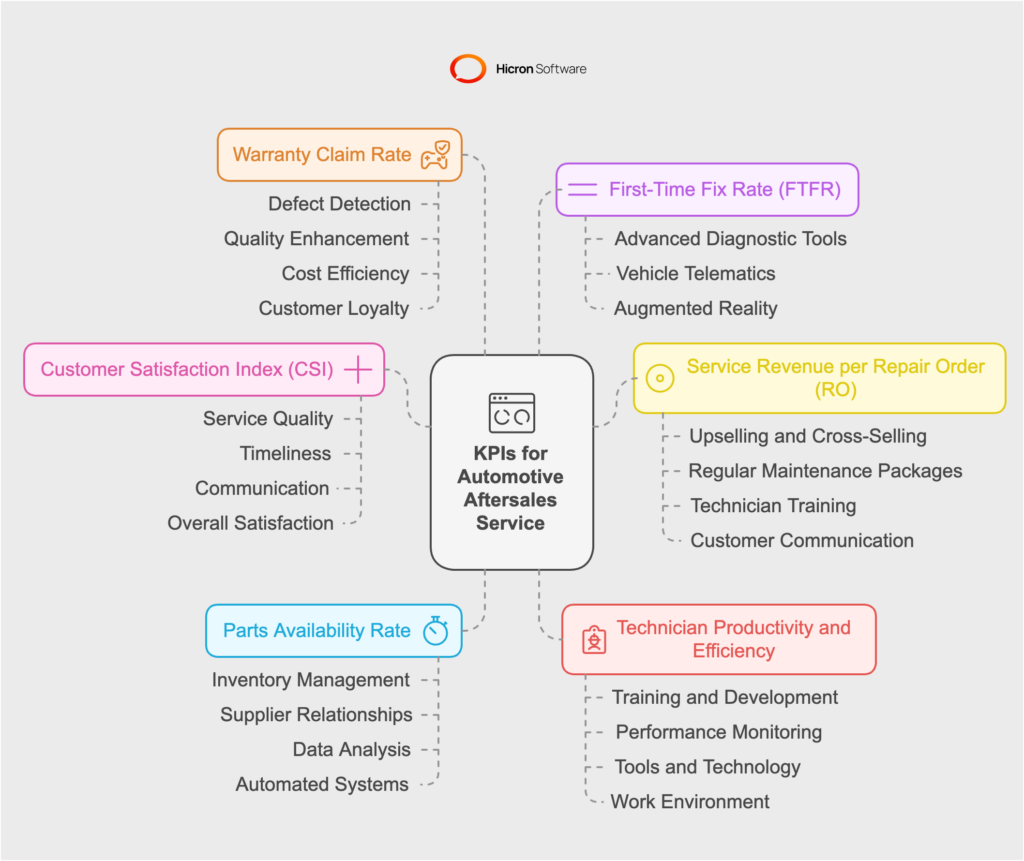

Automotive service department KPIs are essential metrics that measure efficiency, customer satisfaction, and profitability, driving operational excellence and business growth.

By focusing on these essential KPIs and leveraging digital tools, automotive businesses can optimize their aftersales service operations, resulting in improved customer satisfaction, increased efficiency, and enhanced profitability.

The evolving role of the Customer Satisfaction Index (CSI) in a digitally-driven service landscape cannot be overstated. As customer expectations rise with the advent of digital technologies, measuring CSI becomes crucial. Digital tools and analytics provide more precise and immediate feedback mechanisms, enabling businesses to capture real-time customer sentiments. Methods to measure and enhance CSI using these tools include deploying automated surveys, monitoring social media feedback, and utilizing AI-driven sentiment analysis to gain deeper insights into customer experiences.

CSI is typically measured through customer surveys that assess:

The First-Time Fix Rate (FTFR) is a critical KPI that reflects the efficiency and effectiveness of repair processes. In the context of digital diagnostics and repair, FTFR gains even more importance as it directly affects customer satisfaction and operational costs. Strategies to leverage digital technologies for improving FTFR include using advanced diagnostic tools, integrating vehicle telematics for remote issue identification, and employing augmented reality (AR) for guided repairs, ensuring technicians can diagnose and fix issues accurately on the first attempt.

FTFR is calculated by dividing the number of vehicles fixed on the first attempt by the total number of repair jobs, then multiplying by 100 to get a percentage.

Strategies to Improve FTFR:

Service Revenue Per Repair Order (RO) measures profitability per service visit, an essential metric in the digital era. Techniques to boost service revenue using digital upselling and cross-selling tactics involve personalized recommendations based on customer data, leveraging CRM systems to present tailored offers, and utilizing e-commerce platforms within dealership websites to promote additional services and products during the booking or service process.

It is calculated by dividing the total service revenue by the number of repair orders within a specific period.

Ensuring optimal parts inventory is fundamental for efficient aftersales service. Digital inventory management systems are important in maintaining high parts availability rates. Approaches to real-time inventory tracking and predictive stock replenishment include implementing IoT sensors for continuous monitoring, using data analytics to forecast demand patterns, and integrating supply chain management software to automate reordering processes, reducing downtime due to parts unavailability.

Divide the number of times a part is available immediately by the total number of parts requested, then multiply by 100 to get a percentage.

Metrics for assessing technician productivity and efficiency are enhanced significantly by digital tools. Performance can be tracked using digital work order management systems, which provide detailed insights into job completion times and accuracy. Initiatives to enhance productivity and efficiency through digital training and support platforms include using virtual reality (VR) for immersive training experiences, providing online knowledge bases and forums for continuous learning, and deploying mobile apps that offer real-time access to technical manuals and diagnostic information.

Technician Productivity: Calculate by dividing the total billed hours by the total hours worked, then multiply by 100 to get a percentage.

Technician Efficiency: Calculate by dividing the standard labor hours by the actual hours worked, then multiply by 100 to get a percentage.

Monitoring and managing warranty claims efficiently is vital for controlling costs and ensuring customer trust. Digital systems streamline this process by automating claim submission and tracking. Reducing warranty costs through predictive maintenance and data analytics involves using machine learning algorithms to identify potential issues before they occur, thus preventing failures that lead to warranty claims. Additionally, digital records of vehicle service histories help in verifying valid claims promptly and accurately.

Divide the number of warranty claims by the total number of units sold or services provided, then multiply by 100 to get a percentage.

By integrating these effective processes, automotive businesses can optimize their aftersales service operations, leveraging digital advancements to deliver exceptional customer experiences, improve operational efficiency, and drive profitability in the digital era.

Implementing online booking and automated scheduling systems is an essential process for optimizing aftersales service. These systems enable customers to book service appointments at their convenience, reducing wait times and enhancing overall satisfaction. Additionally, digital customer communication and reminders play a crucial role in maintaining engagement and ensuring customers are informed about upcoming services, promotions, and any necessary follow-ups. Automated email and SMS reminders help reduce no-shows and improve the efficiency of service operations.

In the digital era, the importance of ongoing training cannot be overstated. Service personnel must be adept at using the latest digital tools and technologies to provide top-notch service. Key focus areas for digital training include mastering digital diagnostic tools, delivering virtual customer service, and understanding cybersecurity measures to protect customer data and maintain trust. Offering continuous learning opportunities through online courses, webinars, and interactive training modules ensures that staff remain updated with industry advancements and best practices.

Leveraging advanced diagnostic tools such as AI, IoT, and machine learning can lead to more accurate diagnostics and repairs. These technologies enable predictive maintenance by analyzing vast amounts of data to foresee potential issues before they escalate. Furthermore, augmented reality (AR) and virtual reality (VR) play significant roles in technician training, providing immersive experiences that enhance learning and skill development. Through AR and VR, technicians can practice complex repair procedures in a controlled environment, resulting in improved accuracy and efficiency during actual service tasks.

Gathering and analyzing customer feedback through digital channels is vital for continuous improvement. Utilizing online surveys, social media monitoring, and direct feedback forms allows businesses to capture real-time insights into customer experiences. Integrating this feedback into service improvement strategies helps identify pain points, streamline processes, and tailor services to better meet customer expectations. By actively listening to customers and making data-driven adjustments, businesses can foster loyalty and satisfaction.

Adopting digital inventory management systems for real-time tracking ensures optimal parts availability while minimizing excess stock. These systems use IoT sensors and RFID tagging to monitor inventory levels continuously. Predictive analytics further enhances inventory management by forecasting demand trends and automating stock replenishment. This approach balances parts availability with cost-efficiency, ensuring that necessary components are always on hand without incurring unnecessary carrying costs.

One notable example of digital transformation in the automotive aftersales service landscape is the collaboration between Hicron Software and a major automotive manufacturer. This partnership involved the creation of a highly customized application designed to enhance quality control for aftersales servicing. Serving over 60,000 users across 140 countries and supporting five automotive brands, the application significantly improved data processing and visualization capabilities. The solution consolidated multiple data sources into a single, streamlined platform, reducing technical debt and optimizing spending. By employing advanced technologies like Angular, Oracle, and Spring Boot, the application provided a robust foundation for continuous service improvement and enhanced customer satisfaction.

Other examples include automotive giants like BMW, which has integrated advanced telematics and IoT technologies into their aftersales services. By using predictive maintenance systems, BMW can anticipate issues before they arise, ensuring that vehicles are serviced at optimal times, thus minimizing downtime and enhancing customer experience. Similarly, Tesla leverages over-the-air (OTA) updates to remotely diagnose and fix software-related issues, providing real-time solutions without requiring the vehicle to visit a service center.

We can draw several key insights and lessons from these implementations:

The importance of Key Performance Indicators (KPIs) and digital processes in delivering exceptional aftersales service cannot be overstated. KPIs such as Customer Satisfaction Index (CSI), First-Time Fix Rate (FTFR), Service Revenue Per Repair Order (RO), and others provide critical insights into performance and operational efficiency, while digital processes like advanced diagnostic tools, digital appointment scheduling, and continuous training platforms help streamline operations, enhance customer experiences, and drive profitability. Automotive service department metrics provide valuable insights into performance, customer experience, and operational efficiency, helping to optimize service delivery and profitability.

Embracing digital transformation is essential for sustained success in aftersales operations, as the integration of AI, IoT, machine learning, and other advanced technologies paves the way for more accurate diagnostics, efficient inventory management, and personalized customer interactions. To achieve aftersales excellence, it is crucial to continuously monitor, evaluate, and refine digital strategies; regular assessment helps identify areas for improvement, ensuring that processes remain effective and aligned with evolving business goals.