11 DevOps Automation Tools to Streamline Your Workflow

- May 21

- 10 min

Out-of-the-box ERP solutions are pre-configured enterprise resource planning systems that come ready to use with standard features and minimal customization. These systems promise faster implementation and lower upfront costs compared to heavily customized ERP solutions.

Enterprise Resource Planning (ERP) systems help businesses manage their core operations from a single platform. They handle accounting, inventory, human resources, and customer relationships all in one place. When choosing an ERP system, companies face a critical decision: use a standard, out-of-the-box solution or invest in extensive ERP customization.

This guide will help you understand how to properly evaluate the risks and benefits of minimal ERP customization. You’ll learn why aligning your ERP system with unique business processes matters and discover a structured approach to making this important decision.

Key Takeaways:

Out-of-the-box ERP solutions come pre-built with standard features that work for most businesses in similar industries. These systems include common business functions like basic

The software vendor has already configured workflows, reports, and user interfaces based on industry best practices and common business needs.

Companies often opt for minimal ERP customization for several reasons:

Many businesses use these standardized ERP solutions successfully. Small manufacturing companies often find basic inventory features work well for their needs. Service businesses may only require standard project management and billing functions. Retail companies frequently use out-of-the-box ERP solutions for point-of-sale and inventory tracking.

However, every business has unique aspects that may not fit standard templates. The challenge lies in determining whether your processes can adapt to the system, or if the system needs to adapt to your processes.

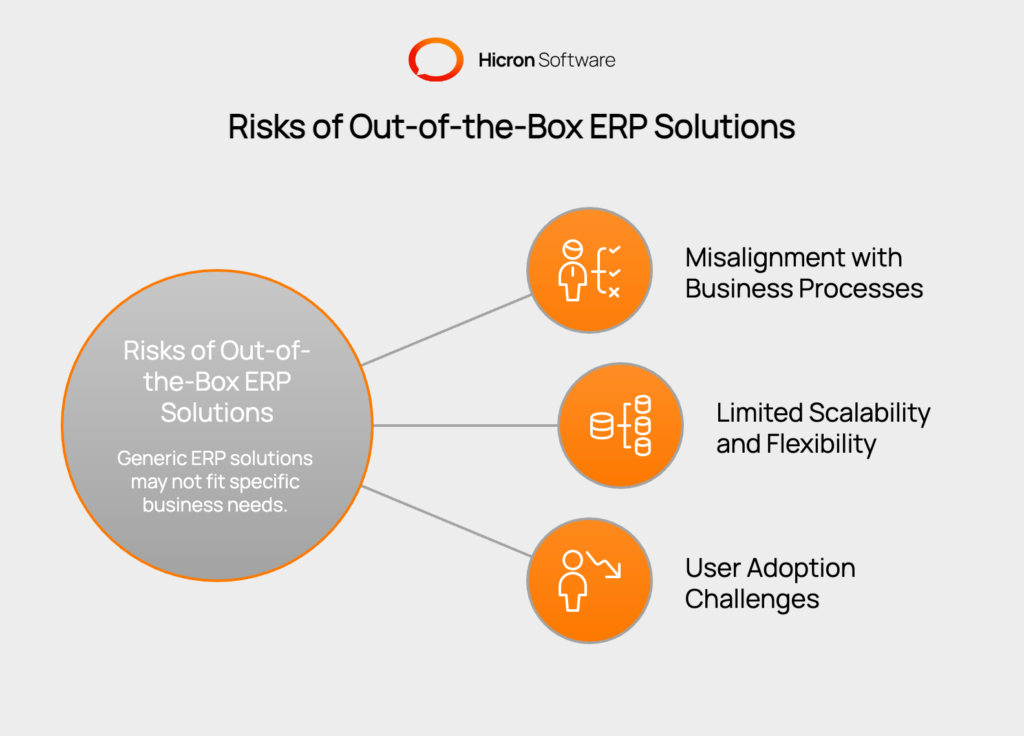

Generic ERP systems are designed for the average business, not your specific operation. This fundamental mismatch can force your team to change proven workflows or create inefficient workarounds.

Consider a custom furniture manufacturer with specialized pricing based on materials, labor complexity, and delivery requirements. An out-of-the-box ERP might only offer basic pricing structures, forcing the company to handle complex calculations outside the system. This creates extra work and increases error potential.

Process disruptions often surface during implementation when employees discover the new system doesn’t support their established workflows. Critical steps may get skipped or performed incorrectly, leading to quality issues or customer complaints.

The problem extends beyond individual tasks. When core business processes don’t align with system capabilities, the entire operation becomes less efficient. Teams spend time fighting the system instead of focusing on actual activities.

Standard ERP features work well when business needs remain stable. But as companies grow or evolve, rigid systems can become constraints rather than enablers.

A growing company might discover that basic reporting features no longer provide the detailed insights needed for strategic decisions. A business expanding into new markets may find the system can’t handle different tax structures or compliance requirements.

These limitations compound over time. Minor constraints today can become major obstacles as business complexity increases. Without flexibility to adapt, companies may outgrow their ERP investment within just a few years.

The scalability issue affects both technical capacity and functional capabilities. The system may handle increased transaction volumes but lack the features needed to manage more complex operations.

When ERP systems don’t match how people actually work, resistance is natural. Employees struggle to complete familiar tasks using unfamiliar methods. This leads to frustration, reduced productivity, and sometimes complete rejection of the new system.

Training becomes more difficult when the system doesn’t align with intuitive business processes. Users need extra time to learn workarounds and remember non-standard procedures. Some may continue using old methods alongside the new system, which defeats the purpose of integration.

Poor user adoption undermines the entire ERP investment. Even the best system fails if people don’t use it properly or consistently. The resulting data quality issues and process gaps can make operations worse than before the implementation.

Initial cost savings from minimal customization are real and attractive. Companies avoid

However, these savings may cost more long-term through reduced efficiency.

Consider total cost of ownership over several years. Systems requiring manual processes to fill gaps may need extra staff time daily. Reports that don’t match business needs may require additional analysis work. These hidden costs can quickly exceed money saved on customization.

Some businesses discover they need customization later anyway, which often costs more than including it from the start. Emergency modifications during live operations create additional risks and expenses.

The true measure isn’t initial investment but long-term value. A system that saves money upfront but hampers operations for years may be more expensive than proper customization.

Fast ERP implementation provides immediate benefits like better data visibility and basic process automation. However, rushing may mean accepting poor fits between system capabilities and business needs.

Quick implementations often skip thorough testing with real-world scenarios. Problems that would surface during extended evaluation only appear after go-live, when they’re more expensive and disruptive to fix.

Pressure to go live quickly may also lead to inadequate training. Users who don’t understand the system fully are more likely to make mistakes or develop bad habits that persist long-term.

The speed advantage disappears if the system requires extensive fixes or user retraining after implementation. Sometimes taking more time upfront prevents bigger problems later.

Out-of-the-box ERP solutions create strong ties to ERP vendors. Companies rely on them for updates, bug fixes, and new features. While this provides stability, it also limits control over system evolution.

If vendors change direction or discontinue features your business depends on, options become limited. You may need to accept changes that don’t benefit your operation or invest in expensive migrations to different systems.

This dependency affects negotiating positions for ongoing contracts. Switching costs increase over time as data and processes become more integrated with vendor-specific approaches.

The relationship works well when vendor and customer interests align. Problems arise when business needs diverge from vendor roadmaps or when vendors prioritize other market segments.

Every business has processes that provide competitive advantage. These might be

When ERP systems support these processes effectively, they become strategic assets.

Proper alignment improves efficiency by eliminating manual workarounds and reducing data entry errors. Employees can focus on work instead of fighting system limitations. Decision-makers get better information because the system captures and reports data matching actual business operations.

Certain industries particularly benefit from customization.

The key is identifying which processes truly differentiate your business and ensuring your ERP system supports them well. Not every process needs customization, but critical ones deserve careful attention.

Alignment also affects long-term adaptability. Systems that match your business logic can evolve more naturally as processes improve. Misaligned systems become increasingly problematic as business sophistication grows.

The table below outlines a step-by-step approach to evaluating the risks and trade-offs of out-of-the-box ERP solutions. It is designed to help businesses make informed choices about customization, system fit, and long-term value.

|

Step |

Description |

Key Actions |

|

1. Conduct a Thorough Needs Assessment |

Document and analyze current business processes to understand specific requirements and identify critical success factors. |

|

|

2. Analyze Fit with Standard Solutions |

Compare business needs against out-of-the-box ERP features to identify gaps and compatibility issues. |

|

|

3. Assess Long-term Scalability |

Evaluate whether the ERP system can grow and adapt with the business over 3-5 years. |

|

|

4. Consider Total Cost of Ownership |

Calculate comprehensive costs beyond initial implementation, including hidden and opportunity costs. |

|

|

5. Engage All Stakeholders |

Involve key personnel from all departments to ensure comprehensive evaluation and buy-in. |

|

|

6. Work with Experienced Partners |

Leverage ERP consultant expertise to avoid common pitfalls and make informed decisions. |

|

Start by documenting current business processes in detail. Map how work flows through your organization, from customer inquiry to final delivery. Identify steps most critical to success and those that differentiate you from competitors.

Interview key stakeholders from each department to understand specific requirements. What information do they need? How do they measure success? What processes cause the most problems currently? This input helps identify where ERP systems must excel versus where standard features suffice.

Create lists of must-have features versus nice-to-have capabilities. Be honest about which functions are truly essential for business operations versus those that would simply be convenient.

Document current system limitations and pain points. Understanding what doesn’t work today helps prioritize improvements in the new system.

Compare documented needs against standard features offered by ERP vendors. Look for gaps where systems don’t support your processes or where workarounds would be necessary.

Test systems with real scenarios from your business. Don’t rely solely on feature lists or vendor demonstrations. Try completing actual transactions and processes using sample data reflecting your complexity.

Pay special attention to reporting and analytics capabilities. Can systems provide information managers need for decisions? Can they handle your specific data structures and relationships?

Evaluate integration requirements with existing systems. Out-of-the-box solutions may not connect easily with specialized software your business depends on.

Consider not just current needs but where your business might be in three to five years. Will systems grow with you? Can they handle increased transaction volumes, additional locations, or new product lines?

Evaluate vendor track records for adding new features and capabilities. Do they regularly enhance out-of-the-box offerings? Are they investing in areas that matter to your industry?

Think about changing business models or market conditions. Will the system adapt if your company needs to modify operations or enter new markets?

Review upgrade paths and version migration processes. How disruptive are major system updates? What happens to customizations during upgrades?

Calculate costs beyond initial software licenses and implementation. Include ongoing maintenance, user training, and support expenses. Factor in costs of workarounds or additional staff time needed to handle functionality gaps.

Consider risk costs of system limitations. What would happen if reports are delayed or inaccurate? How much would it cost if systems couldn’t handle peak transaction volumes?

Compare total costs against customization expenses. Sometimes spending more upfront saves money over system lifetimes.

Include opportunity costs in your analysis. How much business value is lost if systems don’t support optimal processes or decision-making?

Include representatives from every department that will use the ERP system. Their input during evaluation helps identify issues early and builds support for final decisions.

Create formal evaluation teams with clear responsibilities. Have them test scenarios, review documentation, and provide structured feedback. This approach prevents important considerations from being overlooked.

Make sure decision-makers understand trade-offs involved. Present options clearly with pros, cons, and cost implications so they can make informed choices.

Get commitment from senior leadership for whatever approach you choose. ERP success requires sustained support throughout implementation and beyond.

ERP consultants bring experience from similar implementations and can help avoid common pitfalls. They understand capabilities and limitations of different systems and provide objective advice.

Look for consultants who have worked in your industry and understand specific challenges. They should reference similar situations and explain how other companies handled comparable decisions.

However, consultants may have biases toward certain vendors or approaches. Get multiple opinions and verify recommendations against your own analysis.

Consider consultants’ post-implementation support capabilities. ERP success often depends on ongoing optimization and user support after go-live.

This table helps businesses determine which processes should use standard ERP features versus custom solutions. Making the right choice for each business function ensures optimal system performance while controlling costs and complexity.

|

Standard ERP Features |

Custom ERP Solutions |

|

Basic accounting and financial reporting |

Unique pricing models or complex pricing structures |

|

Human resources management and payroll |

Specialized quality control processes |

|

Standard inventory management |

Industry-specific compliance requirements |

|

General customer relationship management |

Proprietary workflows that provide competitive advantage |

|

Basic procurement and purchasing |

Custom reporting for specialized decision-making |

|

Standard project management |

Unique customer service processes |

|

General sales order processing |

Specialized manufacturing processes |

|

Common business intelligence and analytics |

Complex integration with legacy systems |

|

Standard document management |

Unique supply chain management processes |

|

Basic vendor management |

Custom approval workflows |

|

General asset management |

Specialized regulatory reporting |

|

Standard email and communication tools |

Industry-specific data capture requirements |

The most successful ERP implementations usually combine standard features with targeted customization. Use out-of-the-box functionality for common business processes like basic accounting, human resources, and standard inventory management.

Reserve customization for processes that truly differentiate your business or are critical to operations. If specific workflows help you serve customers better or operate more efficiently than competitors, customization may be worthwhile.

Prioritize customizations that provide clear competitive advantage. Avoid modifying processes just because they differ from standard approaches. Each customization should provide demonstrable value justifying its cost and complexity.

Consider phased implementation approaches. Start with standard features and add customizations over time as you better understand how systems work in your environment. This reduces initial risk while preserving options for future enhancement.

Be careful not to over-customize systems. Extensive modifications make systems harder to maintain, more expensive to upgrade, and more complex for users to understand.

Key Recommendations:

The goal is finding the right balance for your specific situation. Some businesses thrive with minimal customization while others need extensive modifications for success. Make this decision based on careful analysis rather than assumptions.

Implementing out-of-the-box ERP solutions with minimal customization requires careful consideration of both advantages and potential pitfalls. While these systems promise benefits like

they may present major risks if they do not match the business’s operational needs. The challenges faced by the waste management industry with SAP ERP make this clear. Standard modules often could not address critical requirements such as

When ERP features fail to support these unique processes, companies are compelled to either abandon proven workflows or develop costly workarounds. The cost savings at the outset can quickly be overtaken by

Ultimately, the key to ERP success is not just choosing between standard and custom options, but ensuring that the solution aligns closely with the core processes that define and drive the business. Careful alignment is vital for long-term operational effectiveness and competitive advantage.

The waste management case illustrates the crucial importance of aligning ERP capabilities with specific business processes prior to implementation. Success requires

Companies should conduct thorough system evaluations rather than relying solely on vendor promises, ensuring the chosen ERP solution can genuinely support their operational requirements without forcing disruptive process changes.

Short-Term Risk and Trade-off Formula

Focuses on the immediate costs, benefits, and risks associated with implementation and initial operation.

Short-Term Impact = (Implementation Costs + Customization Costs + Training Costs + Risk Costs) – (Efficiency Gains + Cost Savings)

Definitions:

Long-Term Risk and Trade-off Formula

Considers scalability, adaptability, and total cost of ownership over time.

Long-Term Impact = (Total Cost of Ownership + Opportunity Costs + Upgrade Costs + Risk Costs) – (Scalability Benefits + Competitive Advantage + Long-Term Savings)

Definitions:

Key Considerations:

ERP success depends on careful planning and consistent execution throughout implementation.

The biggest risk is misalignment between standard system processes and your unique business needs. This can force teams to change proven workflows in ways that reduce efficiency or create workarounds that increase complexity and error rates.

Thorough evaluation typically takes 3-6 months, depending on business complexity. This includes documenting current processes, testing potential solutions, engaging stakeholders, and making final decisions. Rushing this process often leads to poor choices that are expensive to correct later.

Customization is worthwhile when standard features don’t support processes critical to your competitive advantage or operational success. Focus on customizing areas where generic solutions would force inefficient workarounds or prevent effective customer service.

Yes, but post-implementation customizations are usually more expensive and disruptive than including them in initial projects. Plan for essential customizations upfront rather than trying to add them while systems are live.

Measure success through operational metrics like process efficiency, data accuracy, user adoption rates, and time to complete key tasks. Also track business outcomes like customer satisfaction, inventory management, and decision-making speed to ensure systems support strategic goals.