What is the Pre-Delivery Inspection in Automotive

- March 18

- 21 min

Pre-Delivery Inspection (PDI) in automotive acts as a final checkpoint before a vehicle is delivered to the customer, ensuring that it is in perfect condition, free from defects, and ready for use. This process not only helps in building customer trust and loyalty but also significantly contributes to the reputation and operational efficiency of automotive businesses. But how do you digitize pre-delivery inspection?

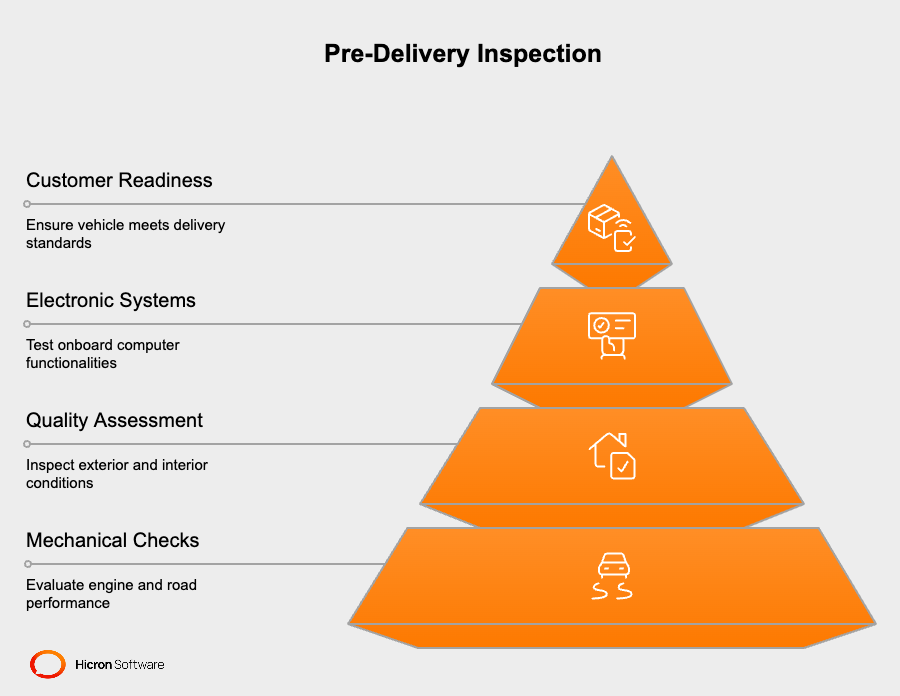

Pre-Delivery Inspection (PDI) is a comprehensive evaluation process conducted on vehicles before they are handed over to customers. This inspection covers various aspects of the vehicle, including mechanical functionality, exterior and interior quality, and the performance of electronic systems. The digitized Pre-Delivery Inspection process is meticulously designed to identify and rectify any issues, ranging from minor aesthetic flaws to critical mechanical problems, ensuring that the vehicle adheres to the manufacturer’s standards and specifications.

Automotive manufacturers and dealerships have specialized teams of technicians and inspectors who are responsible for conducting PDIs. These professionals use a detailed checklist that encompasses all the critical inspection areas, ensuring nothing is overlooked. The checklist typically includes engine checks, road tests, fluid levels, tire pressure adjustments, and the verification of onboard computer systems. Any issues identified during the Pre-Delivery Inspection are addressed and resolved before the vehicle is deemed ready for delivery.

The significance of digitized Pre-Delivery Inspection (PDI) in the automobile industry cannot be overstated, particularly in terms of enhancing customer satisfaction and loyalty. By ensuring that vehicles are in impeccable condition at the time of delivery, businesses can significantly reduce the likelihood of customer complaints and returns. This leads to higher levels of customer satisfaction and fosters a positive brand image and reputation in the market.

Pre-delivery inspection acts as an automotive quality control mechanism, helping businesses identify and address potential manufacturing defects or issues before they reach the customer. This proactive approach can lead to cost savings by reducing warranty claims and the need for post-sale repairs. Additionally, the insights gained from PDIs can be invaluable for manufacturers, providing feedback that can be used to improve production processes and vehicle design.

Pre-delivery inspection is an essential component of the automotive industry, serving as a critical bridge between the final stages of production and customer satisfaction. By ensuring that every vehicle meets the highest standards of quality and performance, digitized Pre-Delivery Inspection contributes significantly to the success and sustainability of automotive businesses, reinforcing customer trust and driving operational excellence.

Pre-delivery inspection (PDI) remains a significant phase in the automotive industry. It ensures that vehicles meet both manufacturer specifications and customer expectations before delivery.

Traditionally, this process involves a comprehensive checklist that covers various aspects of the vehicle, including its mechanical functionality, aesthetics, and safety features. Sources like Carwow and Tata Capital highlight the importance of PDIs in identifying any defects or issues that need rectification, ensuring that the vehicle is in perfect condition for the customer.

Traditional Pre-Delivery Inspection methods are thorough but can be time-consuming and rely heavily on the expertise and diligence of the inspection team. The process involves a series of manual checks, from engine tests to cosmetic inspections, performed by dealership technicians or manufacturers. While effective, these methods have limitations, such as the potential for human error and the difficulty of keeping up with the increasing complexity of new vehicle technologies.

As vehicle technology advances, the traditional PDI process standardization faces challenges in adequately inspecting and testing modern features, such as advanced driver-assistance systems (ADAS) and electric vehicle components. This complexity requires more specialized knowledge and equipment, potentially straining dealerships’ and manufacturers’ resources.

The evolving landscape of the automotive industry, marked by rapid technological advancements and increasing customer expectations, necessitates an upgrade and modernization of the Pre-Delivery Inspection procedure.

Integrating technology into PDI – such as diagnostic software, automation tools, and digital checklists – can enhance accuracy, efficiency, and inspection consistency. For instance, digital tools can streamline the PDI process, automatically recording data and flagging issues for further review, thereby reducing the likelihood of human error.

It is important to train and equip PDI teams with the latest knowledge and tools to handle new vehicle technologies. This includes understanding electric vehicles, hybrid systems, and ADAS functionalities. Adapting PDI processes to these new technologies ensures thorough inspections and boosts customer confidence in the quality and safety of their vehicles.

While traditional Pre-Delivery Inspection methods have served the automotive industry well, modernization is clearly needed to keep pace with technological advancements and evolving customer demands. By integrating technology and enhancing the skills of Pre-Delivery Inspection teams, the automotive industry can ensure that digitized Pre-Delivery Inspections remain a robust safeguard of vehicle quality and customer satisfaction.

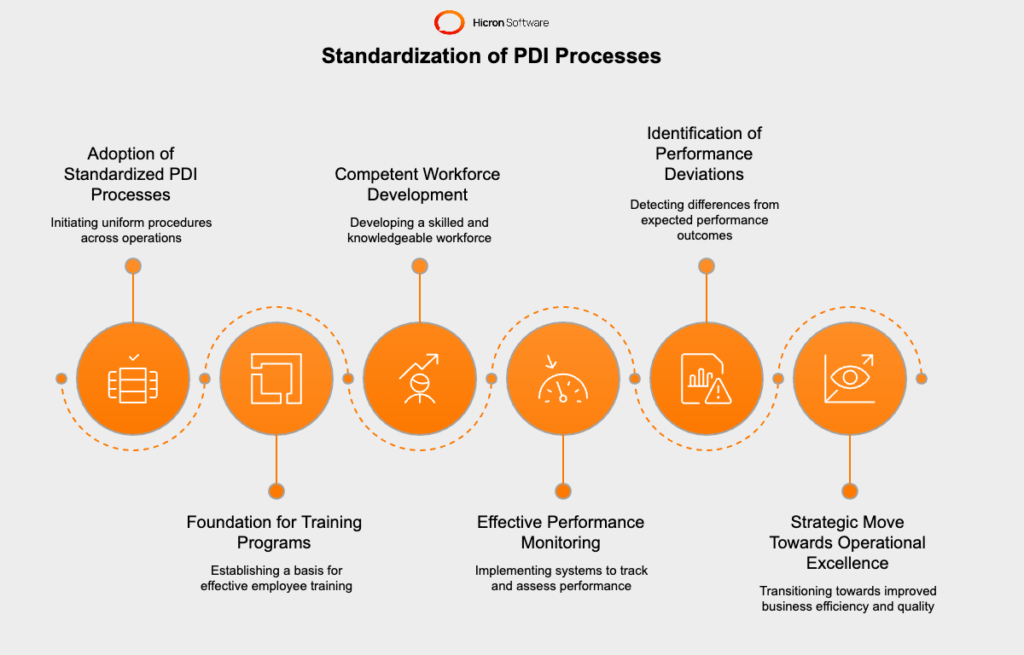

The modern business landscape is increasingly recognizing the value of standardization across various operational processes as a catalyst for growth and efficiency. In the realm of digitized Pre-Delivery Inspection (PDI) within the automotive industry, the shift towards standardization is becoming more pronounced.

Standardization in PDI processes refers to establishing uniform procedures and criteria for inspecting vehicles before they are delivered to customers. This approach ensures that every vehicle meets the same high standards of quality and safety, irrespective of where or when the inspection takes place.

Standardization plays a big role in enhancing the effectiveness and reliability of PDI processes. Standardizing PDI processes can lead to significant improvements in automotive quality control and operational efficiency. By defining clear, consistent guidelines and expectations, businesses can ensure that every vehicle is inspected thoroughly and uniformly, minimizing the risk of oversights and inconsistencies.

The adoption of standardized PDI processes streamlines operations and significantly impacts staff training and performance monitoring. Standardized procedures provide a solid foundation for training programs, enabling new employees to quickly understand their roles and responsibilities. This clarity in training leads to a more competent workforce capable of maintaining high-quality standards across all inspections.

Standardization facilitates the effective monitoring of staff performance. With uniform benchmarks in place, managers can more easily identify deviations from expected outcomes, recognize exemplary performance, and address areas where additional training or resources may be needed. This level of oversight is essential for continuous improvement and ensuring that the PDI process standardization remains efficient and effective over time.

The shift towards standardization in PDI processes represents a strategic move towards operational excellence. By embracing standardization, businesses in the automotive industry can achieve higher levels of consistency, reduce errors, improve efficiency, and enhance staff training and performance monitoring.

As the industry continues to evolve, the importance of standardization will undoubtedly grow, further establishing its role as a key driver of quality and customer satisfaction.

This shift from traditional, manual methods to digital processes is not just a trend but a game changer in how businesses ensure product quality and consistency before reaching the customer. The movement towards digitized PDI is driven by the need for efficiency, accuracy, and adaptability in today’s fast-paced market environments.

Digitized PDI leverages technology to automate and streamline inspection processes. This approach utilizes digital checklists, real-time data capture, and analytics tools to conduct thorough inspections of products or vehicles before they are delivered to customers.

The benefit of digitized PDI standardization in the automotive industry over traditional methods is its ability to provide instant feedback and data analysis, which can be used to identify trends, predict potential issues, and implement corrective actions much more rapidly.

Another key benefit is the reduction of human error. Digitized PDI automates the inspection process, minimizing the risk of oversights and inaccuracies that can occur with manual checks. This leads to higher quality control standards and ensures that customers receive products that meet their expectations and comply with safety regulations.

One of the primary challenges of manual Pre-Delivery Inspection processes is the variability and inconsistency that can arise from human involvement. Different inspectors may have varying interpretations of inspection criteria, leading to inconsistent outcomes.

Digitization addresses this challenge by providing standardized digital checklists and procedures that ensure every inspector conducts the PDI similarly, promoting uniformity across all inspections.

Digitized Pre-Delivery Inspection processes are equipped to handle the increasing complexity of products, especially in industries like automotive, where new technologies and features are continually being introduced. Digital tools can be updated to include new inspection criteria, ensuring that PDIs remain relevant and comprehensive as product specifications evolve.

Standardization through digitization also enhances staff training and performance monitoring. With clear, consistent guidelines and digital tracking of inspections, it becomes easier to identify areas where training may be needed and to monitor inspector performance over time. This not only improves the quality of PDIs but also helps in building a skilled and efficient workforce.

The digitization of Pre-Delivery Inspection processes represents a significant leap forward in how businesses ensure the quality and safety of their products before delivery. By offering advantages such as increased efficiency, reduced errors, and the promotion of standardization, digitized Pre-Delivery Inspection is setting a new standard in automotive quality control practices.

As technology continues to evolve, digitization’s role in Pre-Delivery Inspection will undoubtedly expand, further enhancing its impact on business operations and customer satisfaction.

Vehicle Management Systems (VMS) have emerged as a cornerstone in the automotive and transportation industries, offering an integrated approach to managing all aspects of vehicle operations. These systems encompass a wide range of functionalities, including procurement, sales, maintenance, and service processing, thereby serving as a comprehensive tool for fleet management.

The primary role of VMS in the automotive industry is to streamline and optimize the management of vehicle fleets. By providing a unified platform for all vehicle-related processes, VMS enables businesses to gain actionable insights into their operations, improve efficiency, and reduce costs. For instance, SAP’s vehicle management system is designed to handle both business and technical master data for each vehicle, ensuring seamless integration with key SAP components and facilitating comprehensive fleet management.

Integrating digitized Pre-Delivery Inspection (PDI) processes with Vehicle Management Systems offers several significant opportunities and benefits:

The integration of digitized PDI processes with Vehicle Management Systems represents a significant advancement in the automotive industry. This synergy of pre-delivery inspection software enhances the efficiency and accuracy of vehicle inspections before delivery and leverages the power of VMS to optimize fleet management, making it an invaluable strategy for businesses looking to stay competitive in today’s fast-paced market.

Through improved data accuracy, streamlined operations, and enhanced decision-making capabilities, businesses can achieve higher levels of operational excellence and customer satisfaction.

By standardizing and digitizing PDI processes, automotive companies are enhancing operational efficiency, reducing errors, and improving customer satisfaction. Here are some real-world examples and the impact these initiatives have had on their operations and customer experience.

An article from Whatfix.com discusses the broader scope of automotive digital transformation within the automotive industry, including the standardization and digitization of PDI processes.

Companies leveraging these digital capabilities have reported significant improvements in inspection accuracy, quicker turnaround times, and enhanced customer trust. By implementing digital checklists and automated systems for PDI, these businesses can ensure that every vehicle meets its quality standards before delivery, reducing the likelihood of customer complaints and returns.

The research highlighted on ScienceDirect investigates the effects of process digitalization initiatives (PDI) within the automotive sector. The study illustrates how an automotive company implemented a digital PDI system, leading to increased operational efficiency and dynamic capability. This initiative allowed the company to rapidly adapt to changes and challenges, significantly enhancing its competitive edge.

The digitized PDI process standardization also provided comprehensive data analytics, enabling the company to identify potential issues proactively and improve vehicle quality pre-delivery.

McKinsey & Company offers insights into the successful automotive digital transformations of automotive suppliers, including aspects related to PDI. The blueprint suggests that leading automotive suppliers mastering digital transformation, including PDI standardization and digitization, are experiencing substantial benefits.

These include cost reductions due to fewer manual errors, improved workflow efficiency, and higher customer satisfaction because of the reliability and transparency offered by digital PDI systems.

A publication on ResearchGate focuses on digitalization dynamics, such as user interface innovations within automotive settings, which directly impact PDI processes. By innovating the user interface used in PDI processes, an automotive company managed to enhance the user experience significantly, making the inspection process more intuitive and efficient for technicians.

This improved operational efficiency and ensured a higher level of detail and accuracy in pre-delivery inspections, leading to better customer feedback on vehicle quality.

These case studies showcase the undeniable impact of digital transformation in the automotive industry, particularly in standardizing and digitizing PDI processes. Through these innovations, companies are not only optimizing their operations but are also setting new standards for customer satisfaction.

The continuous evolution of digital technologies promises even more opportunities for automotive companies to refine their PDI processes further and maintain a competitive advantage in the evolving market landscape.

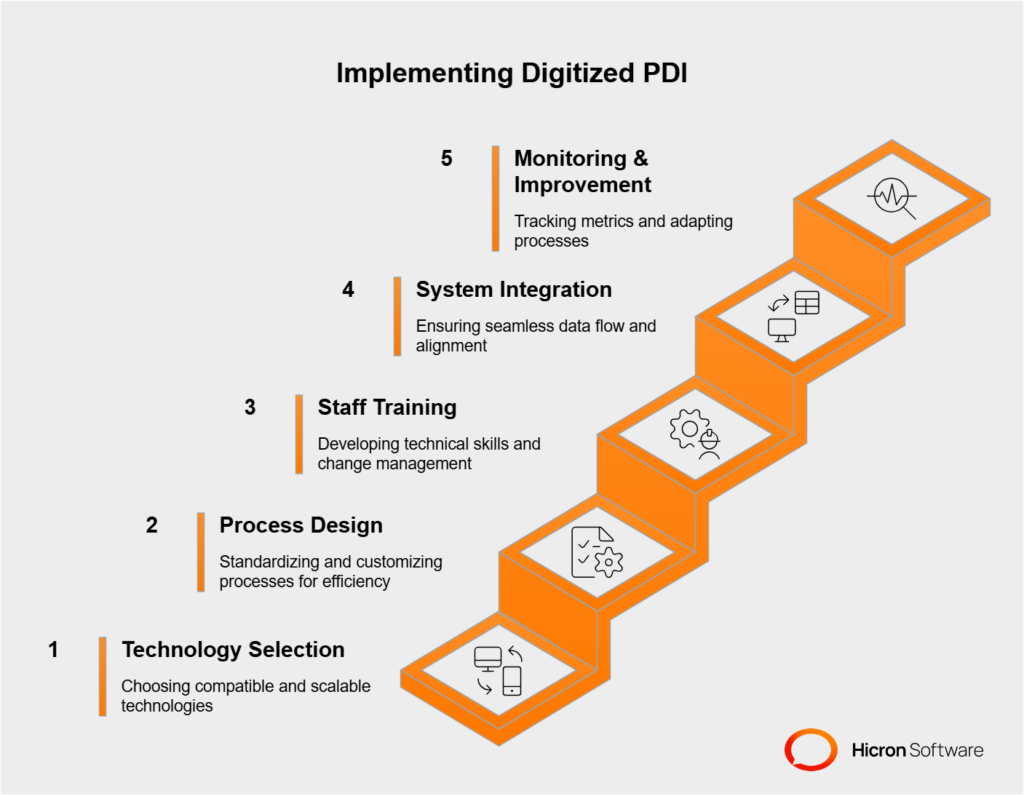

Implementing standardized and digitized Pre-Delivery Inspection (PDI) processes represents a significant step towards enhancing operational efficiency, quality control, and customer satisfaction in the automotive industry.

However, the transition from manual to digital Pre-Delivery Inspection processes involves careful planning and consideration of several key factors. Here are the main considerations that automotive companies should address during the implementation of standardized and digitized PDI processes.

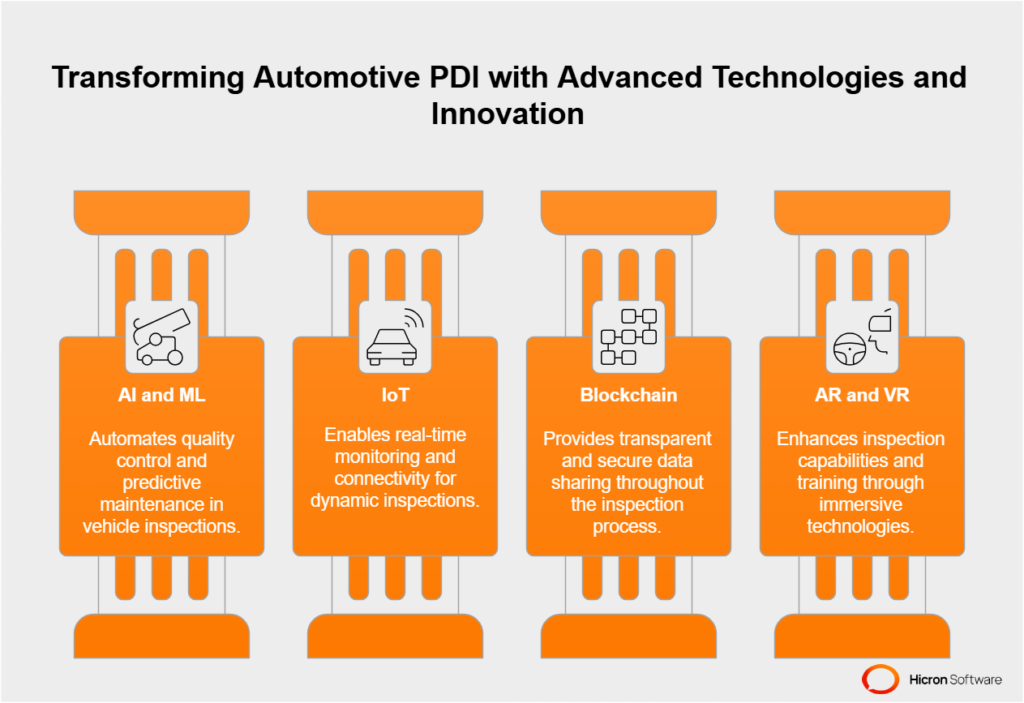

The future of Pre-Delivery Inspection (PDI) in the automotive industry is poised for significant evolution, driven by rapid technological advancements. The integration of digital and standardized PDI processes with emerging technologies such as Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) heralds a new era of efficiency, accuracy, and customer satisfaction.

The future of Pre-Delivery Inspection in the automotive industry is bright, with emerging technologies offering unprecedented opportunities to enhance the efficiency, accuracy, and outcomes of pre-delivery inspections. These advancements promise not only to transform the PDI process standardization but also to elevate the overall value and experience delivered to customers.

By adopting a standardized approach to PDI, companies ensure consistency and reliability across all inspections, laying the foundation for high-quality outcomes. Digitization further augments this process, introducing efficiency, precision, and scalability that manual methods simply cannot match.

Standardization minimizes variability and errors in the inspection process, ensuring every vehicle meets the same high standards of quality before it reaches the customer. This bolsters the brand’s reputation for reliability and significantly reduces costly recalls and rework. Conversely, digitization leverages cutting-edge technologies like AI, ML, and IoT to streamline operations, automate time-consuming tasks, and provide real-time data analytics for informed decision-making. The combination of these two elements results in a robust framework for conducting PDIs that can adapt to future trends and demands.

For automotive companies striving for leadership in a highly competitive market, upgrading to standardized and digitized Pre-Delivery Inspection procedures backed by pre-delivery inspection software is not just an option – it’s a necessity. This transition promises immediate improvements in efficiency and quality and positions companies to leverage emerging technologies and trends seamlessly.

Whether you’re a manufacturer, dealer, or supplier, the future of automotive quality control lies in modernizing your PDI processes. This investment can unlock significant business value, enhance operational outcomes, and deliver unforgettable experiences for your customers.

Consider this upgrade an investment in your company’s future, one that will pay dividends through improved operational metrics, customer loyalty, and adaptability to industry evolution. The era of digital transformation in the automotive industry is here, and standardizing and digitizing PDI processes is your first step towards securing a competitive edge in this dynamic landscape. Get in touch!